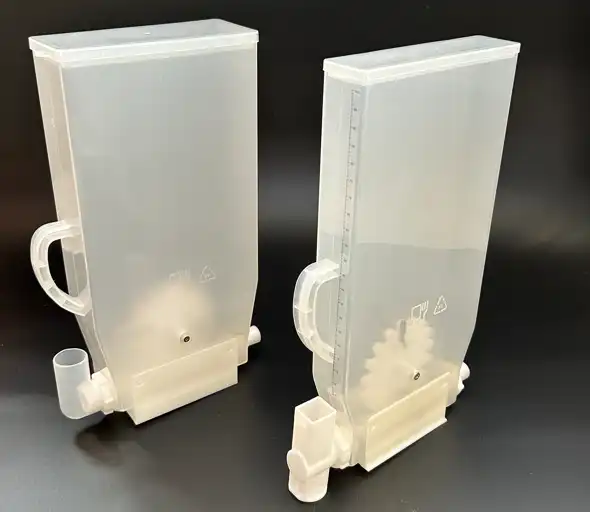

Coffee Vending Machine Ingredient Canisters

1-5L 500-3000g Customized size:like 25*15*6 cm/38*18*6.4/38*18*4.2

Moisture proof and drop coffee vending machine plastic canister.

Food grade plastic powder canister, also suitable for hot chocolate, sugar,nuts, candies, milk powder and so on.

Lead time: 7 Days.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Description

Specification Parameter

| Feature | Specification |

|---|---|

| Material | Food-grade plastics |

| Capacity | Customizable |

| Dispensing Mechanism | Auger-based, gravity-fed, or rotary valve system |

| Dimensions | See detailed below |

| Weight | Varies with capacity and material |

| Model | Specifications |

| A1 | W60*136*L149-188mm/700ml/500g |

| A2 | W60*H136,depth149-188mm700ml/500g |

| B1 | W75*H230,depth 171-203mm/2000ml/1500g |

| B2 | W75*H230*L 171-203mm/2000ml/1500g |

| C | W42.5*H239*L 180-235mm/1200ml/1200g |

| D | W71*H235*L 175-235mm/2000ml/1500g |

| E | W42.5*H366*L 180-235mm/2000ml/1500g |

| F | W71*H366,depth 175-235mm/4000ml/3000g |

| W118 | W118*H350*L216mm/5000g |

| W75 | W75*H350*L216mm/3000g |

| W64 | W64*H350*L216mm/2800g |

| W42 | W42*H350*L216mm/2000g |

| W42A | W42*H245*L216mm |

| W64A | W64*H245*L216mm |

Introduction

Coffee Vending Machine Ingredient Canisters in a coffee vending machine are painstakingly intended to store and apportion various kinds of ingredients, including coffee beans, moment coffee powder, tea leaves, milk powder, sugar, and seasoning syrups. These canisters are commonly produced using solid materials, for example, food-grade plastic to guarantee cleanliness and life span.

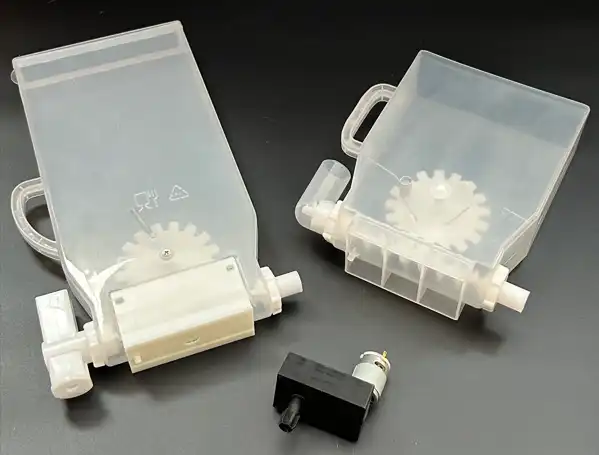

Every canister is furnished with a system for precisely estimating and apportioning the necessary measure of ingredients for each beverage. This instrument might fluctuate relying upon the sort of ingredient being administered, for certain canisters using drills or twistings for powders and granules, while others might utilize siphons for fluids.

One of the critical contemplations in the plan of ingredient canisters is keeping up with newness and flavor respectability. Impermeable seals and hazy materials help to safeguard the nature of the ingredients, guaranteeing that some coffee or tea tastes as delectable as could really be expected.

Moreover, present day coffee vending machines frequently highlight cutting edge innovation, for example, sensors and checking frameworks to follow ingredient levels continuously. This permits administrators to top off canisters quickly, limiting free time and guaranteeing a consistent inventory of refreshments to clients.

The ingredient canisters in coffee vending machines are fundamental parts that add to the proficiency, dependability, and nature of the refreshment administering process. By putting away and administering ingredients precisely and keeping up with their newness, these canisters empower coffee vending machines to convey a wonderful and reliable drinking experience to customers all over the place.

Main Features, Performance, and Market Advantages

Coffee vending machine ingredient canisters accompany a plenty of highlights that add to their excellent exhibition and market benefits. Here are a few key features:

Strong Development: Fabricated utilizing top notch materials, for example, treated steel or food-grade plastics, these canisters are intended to endure the afflictions of consistent use and temperature varieties without compromising the uprightness of put away ingredients.

Particular Plan: Canisters are in many cases measured in plan, considering simple establishment, upkeep, and substitution. This measured methodology upgrades adaptability and versatility, empowering administrators to alter their vending machines as per explicit necessities.

Numerous Compartments: Canisters commonly include various compartments, each assigned for various ingredients. This compartmentalization guarantees productive capacity and apportioning of different parts, limiting cross-tainting and keeping up with flavor virtue.

Exact Apportioning System: Outfitted with accuracy administering components, these canisters guarantee precise part control, accordingly ensuring consistency in taste and quality across all servings.

Coordinated Sensors: Numerous cutting edge canisters are furnished with sensors that screen ingredient levels continuously. This empowers proactive restocking and forestalls occasions of ingredient consumption during top use hours.

Simple Cleaning and Upkeep: Canisters are intended for simple cleaning and support, with separable parts and available insides working with issue free disinfection techniques. This guarantees cleanliness as well as drags out the life expectancy of the gear.

Cost-Effectiveness: By smoothing out the drink administering process and limiting wastage, coffee vending machine ingredient canisters add to massive expense investment funds for administrators. Moreover, their solidness decreases the recurrence of substitutions, further improving expense effectiveness.

Working Principle

-

Ingredient Capacity: It comprise of various compartments, each committed to putting away a particular ingredient, for example, coffee grounds, milk powder, or sugar. These compartments are fixed to keep up with newness and forestall defilement.

Administering Instrument: When a drink is chosen by the client, the vending machine enacts the relating apportioning system related with the necessary ingredient. This can incorporate drill based frameworks for powdered ingredients or rotating valve frameworks for fluid parts.

Segment Control: The apportioning system exactly gauges the necessary part of the chose ingredient and conveys it to the blending chamber or cup underneath. This guarantees steady taste and quality in each serving.

Ongoing Observing: Incorporated sensors consistently screen ingredient levels inside the canisters. At the point when levels fall under a specific limit, the vending machine sends cautions to provoke topping off, forestalling breaks in help.

Cleaning and Upkeep: Occasionally, the canisters go through cleaning and support techniques to maintain cleanliness guidelines and guarantee ideal execution. This normally includes dismantling the parts, cleaning them completely, and assessing for any indications of wear or harm.

Application Field

- Business Settings: Coffee vending machine ingredient canisters find broad use in business settings like workplaces, colleges, and shopping centers, where huge volumes of refreshments are apportioned day to day to take special care of representatives, guests, and clients.

- Friendliness Industry: Lodgings, cafés, and bistros depend on coffee vending machines furnished with cutting edge ingredient canisters to offer a large number of drinks to visitors rapidly and productively, improving in general consumer loyalty.

- Transportation Centers: Air terminals, train stations, and transport terminals introduce coffee vending machines with ingredient canisters to furnish explorers with advantageous admittance to hot refreshments during their excursions.

- Instructive Establishments: Schools, universities, and colleges introduce vending machines outfitted with ingredient canisters to take special care of the caffeine needs of understudies and employees, particularly during test seasons and review periods.

- Retail Conditions: Grocery stores, odds and ends shops, and service stations convey coffee vending machines with ingredient canisters to offer clients newly prepared coffee and different refreshments as a feature of their item contributions.

Topping Motor

Topping Motor is a leading manufacturer and supplier of coffee vending machine ingredient canisters, offering a comprehensive range of products backed by large inventory and complete certifications. With extensive experience in the industry, Topping Motor specializes in providing OEM and ODM solutions tailored to the unique requirements of clients worldwide. Their one-stop standard service encompasses fast delivery, meticulous packaging, and comprehensive support for testing, ensuring the seamless integration of their canisters into any vending machine setup. For inquiries and further information, please contact Topping Motor at sales@huan-tai.org

Send Inquiry

You may like

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)