A vending machine motor is a specialized electric motor used to power various mechanisms within vending machines. These motors are designed to provide precise and reliable operation to dispense products such as snacks, beverages, and other items.

Key features and considerations of vending machine motors include:

Size and Form Factor: Vending machine motor components come in various sizes and shapes to fit different vending machine configurations and requirements. They are typically compact and lightweight to accommodate the limited space available within vending machine enclosures.

Power and Torque: These motors are engineered to deliver the necessary power and torque to operate the vending machine's dispensing mechanisms efficiently. The power output and torque specifications depend on factors such as the weight and type of products being dispensed and the mechanism's design.

Control and Speed Regulation: Vending machine motor components often incorporate control features for precise speed regulation and operation. This allows for accurate product dispensing and ensures consistency in vending machine performance.

Energy Efficiency: Efficiency is an essential consideration for vending machine motors, as they typically operate continuously or intermittently throughout the day. Energy-efficient motors help minimize power consumption and operating costs while maximizing the vending machine's profitability.

Reliability and Durability: Since vending machines are often placed in high-traffic areas and operate in various environmental conditions, the motors must be robust and reliable. They should be capable of enduring frequent use, temperature fluctuations, and other challenging conditions without compromising performance or longevity.

Maintenance Requirements: Low-maintenance design is advantageous for vending machine motors to minimize downtime and maintenance costs. Motors with sealed bearings, durable brushes, and other features that reduce wear and tear are preferred for vending machine applications.

Compatibility and Integration: Vending machine motors should be compatible with the control systems and interfaces used in vending machines. They should integrate seamlessly with other components and subsystems to ensure smooth operation and functionality.

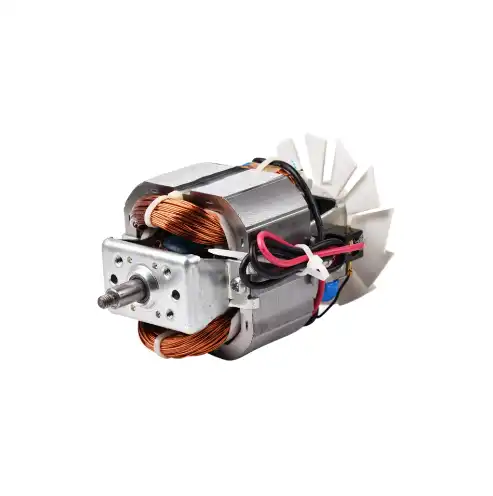

Vending Machine Motor

0-

Coffee Grinder Motor

230V DC971 Grinding Motor Coffee Vending Machine

Type:AC/DC Motor

Dimension:52.4*52.4*120 mm

Power:42W

Warranty: 1 Year

No load speed:10547 rpm -

Vending Machine Spiral Motor

Apply for:100 series,200 series,300 series,310 series, 110 series -

Whipper Motor

Model S2: DC24V / 130R / min 4-8kg torque 50R / 220r output shaft has 6 teeth and 16 teeth. It is used according to the specification of canister

Model J1: DC24V / 130R / min 8-16kg torque feeding motor peristaltic pump drive motor

Model J1A:DC24V / 130R / min 8-16kg torque feeding motor peristaltic pump drive motor

Plastic motor S3:DC24V/130R/50R

.webp)