How does a Vending Coffee Machine Water Tank work?

2024-12-02 10:57:32

Discover the mystery of the vending coffee machine water tank! These genuine parts assume an essential part in conveying your everyday caffeine fix from those helpful mechanized baristas. However, what exactly transpires within these tanks and how do they contribute to the perfect cup of vended coffee?

Distributing coffee machines are wonders of modern convenience, intended to convey an assortment of coffee drinks at the press of a button. At the core of these machines lies the water tank, a part that is fundamental for the coffee-making process. The water tank fills in as the essential repository, putting away and providing the water required for fermenting. It's not only a straightforward compartment, however - the water tank is a perplexing framework that guarantees clean, temperature-controlled water is consistently accessible for fermenting.

Vending coffee machines operate on a fairly straightforward principle. The machine heats water from the tank, grinds fresh coffee beans (or uses pre-ground coffee), and mixes these components under pressure when the user selects a beverage. The water tank's part in this cycle is to give a reliable, clean water supply, kept up at the ideal temperature for coffee extraction.

Water Tank Structure

The construction of a vending coffee machine water tank is planned given usefulness and proficiency. Most of the time, these tanks have a shape like a rectangle or a cylinder so they can fit inside the vending machine and store as much water as possible. The tank can be as small as two liters for small office machines or as large as twenty liters for high-traffic areas, depending on the machine's intended use and location.

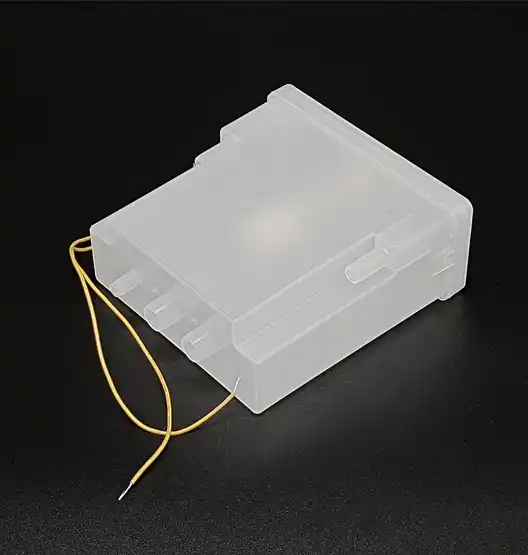

Water tanks are generally produced using food-grade plastics or treated steel. Plastic tanks are lightweight and practical, while treated steel offers unrivaled solidness and better temperature maintenance. The two materials are picked for their protection from erosion and capacity to keep up with water immaculateness.

There are a few essential parts inside the tank. Activated carbon filters are frequently used in filtration systems found in many tanks to remove impurities and enhance the taste of the water. Water levels are frequently monitored with electronic sensors or float balls. High-level tanks may likewise incorporate warming components to keep up with water at the ideal preparing temperature.

Another significant inward part is the power source valve, which controls the water stream from the tank to the blending framework. This valve is made to make sure that only the right amount of water is released for each brew cycle and to prevent backflow.

Water Supply System

The water supply framework in a vending coffee machine water tank is intended for productivity and dependability. There are commonly two principal sorts of water supply frameworks: manual-fill tanks and plumbed-in frameworks.

In manual-fill frameworks, the water tank is filled the hard way. These tanks for the most part have a removable top or an assigned filling port. While this framework requires normal support, it offers adaptability in machine situation as it needn't bother with an immediate water line association.

Plumbed-in frameworks, then again, associate straightforwardly with a structure's water supply. Additional filtration stages and a pressure regulator to guarantee consistent water flow are common features of these systems. Because they don't need to be refilled by hand, plugged-in systems are great for places with a lot of traffic.

Water is delivered to the brewing system whenever it is needed, regardless of how it is filled. A pump takes water from the tank and passes it through a heating element when a drink is chosen. After that, the heated water flows into the brewing chamber, where the coffee grounds are mixed with it. The machine's internal computer controls the entire process, ensuring that each drink has the right amount and temperature of water.

Water Level Monitoring

Successful water level observation is vital for the smooth activity of a vending coffee machine. There are a few strategies used to monitor water levels in the tank.

The least difficult and most conventional technique is the float ball framework. A light ball connected to a pole rises and falls with the water level. This development can set off switches or checks to demonstrate the ebb and flow water level. While basic and dependable, float ball frameworks can now and again stall out or give less exact readings contrasted with additional cutting-edge strategies.

For water level monitoring, numerous modern machines utilize electronic probes or sensors. These sensors can provide highly accurate, real-time data on water levels. A few high-level frameworks utilize ultrasonic sensors the distance between the sensor and the water surface, giving exact level data with practically no moving parts.

Optical sensors are another choice, utilizing light pillars to recognize water levels. These sensors are especially valuable in conditions where mineral development could influence different sorts of sensors.

No matter what technique is utilized, most modern vending coffee machine water tanks integrate cautions or programmed shut-off highlights when water levels get excessively low, forestalling harm to the machine and guaranteeing reliable beverage quality.

Water Quality Management

To produce excellent coffee, the quality of the water is of the utmost importance, and water tanks in vending machines play a crucial role in managing this aspect. To ensure that the water used for brewing is clean and free of impurities that could affect taste or machine performance, many water tanks include multi-stage filtration systems.

A common filtration framework could begin with a dregs channel to eliminate bigger particles. This is many times followed by an enacted carbon channel, which is viable at eliminating chlorine, terrible preferences, and scents. A few high-level frameworks could likewise incorporate particle trade channels to relax water in regions with high mineral substances.

Notwithstanding filtration, some high-end vending machines incorporate UV sterilization systems within the tank. These frameworks utilize bright light to kill microbes and different microorganisms, guaranteeing the water stays protected and new in any event, during times of low use.

Water quality administration likewise stretches out to temperature control. To keep the water at the ideal temperature for coffee extraction, typically between 195°F and 205°F (90°C to 96°C), many tanks have heating elements or are connected to separate boilers.

Vending Coffee Machine Water Tank Manufacturers

It is essential to select a reputable manufacturer when selecting a water tank for your vending coffee machine. Topping Motor, a company with more than a decade of experience manufacturing water tanks for vending coffee machines, is one such manufacturer.

Topping Motor offers a scope of water tanks intended to address different issues and details. The Water tank sx1 in their line of products is ideal for smaller vending machines or those with lower usage rates. They offer the Water tank sx2, which strikes a balance between capacity and space efficiency, for medium-sized businesses. Their largest model, the Water tank sx3, is intended for high-volume locations where frequent refilling is impractical.

Every one of these models is designed considering sturdiness and cleanliness, utilizing food-grade materials that are not difficult to clean and keep up with. They additionally consolidate highlights like level sensors to alarm administrators while topping off is essential, and a few models incorporate implicit filtration frameworks to guarantee water quality.

For those on the lookout for a vending coffee machine water tank, Topping Motor invites requests at sales@huan-tai.org. Their staff can provide in-depth information about their products and assist in selecting the best tank for each vending machine.

References

1. Journal of Food Engineering. (2023). "Water Quality Management in Vending Machine Systems."

2. Vending Times. (2024). "Innovations in Vending Machine Water Tank Design."

3. International Journal of Food Science & Technology. (2022). "Comparative Study of Water Filtration Methods in Coffee Vending Machines."

4. European Vending Association. (2023). "Best Practices in Vending Machine Maintenance."

5. Coffee Science Foundation. (2024). "The Impact of Water Quality on Vended Coffee Taste."

Send Inquiry

You may like