How is the flow range of a liquid flow sensor determined?

2025-01-14 10:28:11

Liquid flow sensors play a crucial role in numerous industrial applications, from monitoring water usage to controlling complex chemical processes. Understanding how the flow range of these sensors is determined is essential for anyone working with fluid systems or selecting the right sensor for their needs.

What Does the Flow Range of a Liquid Flow Sensor Represent?

The flow range of a liquid flow sensor represents the span of flow rates that the sensor can accurately measure. This range is typically expressed as a minimum and maximum flow rate, often in units such as liters per minute (L/min) or gallons per minute (GPM). For instance, a sensor might have a flow range of 0.1 to 10 L/min, indicating that it can reliably measure flow rates within these bounds.

Understanding the flow range is crucial because it directly impacts the sensor's accuracy and functionality. Operating a sensor outside its specified flow range can lead to inaccurate measurements or even damage to the device. The flow range also influences the sensor's resolution, which is the smallest change in flow rate that the sensor can detect.

It's important to note that the accuracy of a liquid flow sensor often varies across its flow range. Many sensors are most accurate in the middle of their range, with accuracy decreasing towards the extremes. This characteristic is why manufacturers often provide accuracy specifications as a percentage of the full scale or as a percentage of the reading, depending on the sensor design.

How Do Manufacturers Specify Flow Range During Design?

- Intended Application: Manufacturers first consider the typical applications for the sensor. Different industries and processes have varying flow rate requirements, which guide the initial range selection.

- Sensor Technology: The choice of sensing technology significantly influences the achievable flow range. For example, ultrasonic sensors might offer a wider range compared to mechanical paddle wheel sensors.

- Physical Constraints: The size of the sensor and the pipe will be installed in place of physical limits on the flow range. Larger pipes can accommodate higher flow rates, while smaller sensors might be limited to lower flows.

- Accuracy Requirements: The desired accuracy across the flow range is a critical factor. Manufacturers may narrow the flow range to achieve higher accuracy or expand it at the cost of some precision.

- Testing and Calibration: Extensive testing is conducted to verify the sensor's performance across the proposed range. This process often leads to adjustments in the specified range to ensure reliability.

- Safety Factors: A safety margin is usually incorporated into the specified range to account for variations in real-world conditions and to prevent damage to the sensor.

The interplay of these factors results in a flow range that balances performance, reliability, and marketability. It's worth noting that some advanced liquid flow sensors offer multiple range settings or auto-ranging capabilities, allowing for greater flexibility in various applications.

How Does Fluid Type Influence the Determination of Flow Range?

The type of fluid being measured has a significant impact on the determination and performance of a liquid flow sensor's flow range. Different fluids have unique physical properties that can affect sensor operation and accuracy:

- Viscosity: Highly viscous fluids like oils or syrups can dampen the movement of mechanical parts in some sensor types, potentially reducing the effective flow range. Manufacturers must account for this when specifying ranges for sensors intended for viscous fluids.

- Density: The density of the fluid affects its momentum and how it interacts with sensor components. Sensors designed for water may need recalibration or redesign for use with denser or lighter fluids to maintain accuracy across the flow range.

- Conductivity: For electromagnetic flow sensors, the fluid's electrical conductivity is crucial. These sensors may have different flow ranges specified for conductive and non-conductive fluids.

- Corrosiveness: Corrosive fluids can damage sensor components over time, potentially altering the effective flow range. Manufacturers may specify more conservative ranges for sensors exposed to corrosive substances.

- Temperature: Fluid temperature can affect viscosity and other properties. Some sensors have different specified flow ranges for different temperature ranges to account for these changes.

To address these variations, manufacturers often provide calibration factors or correction tables for different fluid types. In some cases, specialized sensors are developed for specific fluid categories, such as high-viscosity liquids or aggressive chemicals.

It's also worth noting that some advanced liquid flow sensors incorporate temperature compensation or multi-parameter sensing to adjust for fluid property changes in real-time, helping to maintain accuracy across the specified flow range under varying conditions.

When selecting a liquid flow sensor, it's crucial to consider not just the flow range but also how well that range applies to the specific fluid being measured. Consulting with sensor manufacturers or fluid dynamics experts can help ensure the chosen sensor will perform accurately in the intended application.

Liquid Flow Sensor Supplier

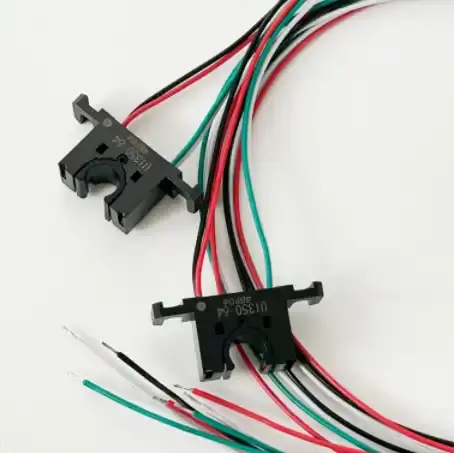

Understanding the intricacies of liquid flow sensor flow ranges is crucial for selecting the right sensor for your application. The liquid flow sensor from Topping Motor Company exemplifies the careful consideration of these factors in sensor design. With a flow range of 0.1 to 10 liters per minute, it offers precise measurement across a wide spectrum of applications. The sensor's accuracy level, ranging from ±1% to ±5% of the reading, demonstrates the typical variation in precision across the flow range.

Topping Motor's sensor is designed to operate under pressures from 0 to 10 bar, making it suitable for various industrial setups. Its compatibility with diverse fluids, including water, milk, and syrup, showcases how manufacturers account for different fluid properties in sensor design. The wide operating temperature range of -20°C to 85°C further illustrates the consideration of environmental factors in determining sensor capabilities.

If you're in the market for a versatile and reliable liquid flow sensor, Topping Motor Company's offering could be an excellent choice. For more information or to discuss your specific needs, please don't hesitate to contact us at sales@huan-tai.org. Our team of experts is ready to help you find the perfect flow measurement solution for your application.

References

- Baker, R. C. (2000). Flow measurement handbook: industrial designs, operating principles, performance, and applications. Cambridge University Press.

- Lipták, B. G. (2003). Instrument Engineers' Handbook, Volume One: Process Measurement and Analysis. CRC press.

- Spitzer, D. W. (2001). Flow measurement: practical guides for measurement and control. ISA.

- Pereira, M. (2009). Flow meters: Part 1. IEEE Instrumentation & Measurement Magazine, 12(1), 18-26.

Send Inquiry

You may like