Is it necessary to have a Coffee Machine O Rings?

2025-01-02 15:06:20

1. Introduction

When it comes to making coffee, accuracy and consistency are essential for producing the ideal cup. While the quality of the beans, the size of the grind, and the brewing methods get a lot of attention, there is a small but very important factor that affects how well coffee machines work: the Coffee Machine O Rings Even though they may appear insignificant, these rings made of rubber or silicone are actually necessary for the majority of coffee makers—from basic home brewers to high-end cafe espresso machines—to function properly.

Mechanical gaskets called O-rings, which get their name from their circular shape, are made to stop leaks in a variety of machinery. Multiple essential functions ensure that coffee machines operate effectively and produce high-quality coffee. It is impossible to overstate the importance of O-rings in coffee-making equipment; From manual espresso makers to fully automatic bean-to-cup machines, they can be found in almost any type of coffee maker.

O-rings are crucial because they can seal the coffee machine's various components in an airtight and watertight manner. This fixing property is vital in keeping up with appropriate strain, forestalling spills, and guaranteeing that water and espresso course through the machine as expected. Coffee machines would be prone to leaks, pressure loss, and ultimately poor performance without these tiny but powerful components.

We'll delve deeper into the world of coffee machine O-rings to learn more about how they work, where they are located in various machines, and how they affect coffee machine performance and longevity. Coffee enthusiasts and professionals alike can appreciate the engineering behind their favorite brewing devices and recognize the significance of regular maintenance by understanding the function of O-rings.

2. O-rings in coffee machines

O-rings are utilized in different areas all through espresso machines, each filling a particular need in the blending system. The exact location and number of Coffee Machine O Rings in a coffee machine can vary from model to model, but some common locations include:

1. Portafilter: O-rings are typically located at the portafilter's edge in espresso machines. These rings make a tight seal between the portafilter and the gathering head, guaranteeing that water courses through the coffee beans at the right tension without spilling.

2. Head of Group: Numerous O-rings are frequently present in the group head, which is where the portafilter is attached to the machine. These aid in ensuring that the portafilter and the machine's internal components are properly aligned and sealed.

3. Connectors to the Boiler: At high temperatures and pressures, O-rings are used to seal connections between the boiler and other machine components to prevent steam and water leaks.

4. Connecting the Pump: O-rings are frequently used to seal the connections of the water pump in a coffee machine, ensuring that the water flows smoothly and without leaking.

5. Assembly of Valves: O-rings are used in the coffee machine's steam wand and hot water dispenser valves to keep them functioning properly and prevent leaks.

6. Tank of water: O-rings are frequently used to create a watertight seal between the machine's water intake system and the machine's removable water tank in machines.

O-rings play a crucial role in the piston mechanism of manual espresso makers, such as lever machines, ensuring proper pressure buildup and release. O-rings are often found in the water distribution system of automatic drip coffee makers. They help to keep the pressure and flow of water constant.

O-rings for coffee machines are typically made of EPDM (Ethylene Propylene Diene Monomer) rubber or food-grade silicone. These materials were chosen for their long-term durability, resistance to heat, and capacity to keep their sealing properties despite being used repeatedly. The machine's specific requirements, as well as the temperatures and pressures to which the O-rings will be subjected, often determine which material to use, silicone or EPDM.

3. Functions of O-rings

The primary function of Coffee Machine O Rings in coffee machines is to create and maintain seals that prevent leaks of water, steam, and air. This sealing function is critical for several reasons:

1. Pressure Maintenance: In espresso machines, maintaining the correct pressure is crucial for proper extraction. O-rings help ensure that the high pressure (typically 9 bars) required for espresso brewing is maintained throughout the system. They prevent pressure loss that could occur through small gaps or connections between components.

2. Water Flow Control: O-rings help direct water flow through the intended pathways within the machine. This is particularly important in ensuring that water passes through the coffee grounds evenly, leading to consistent extraction and flavor.

3. Steam Containment: For machines with steam wands, O-rings play a vital role in containing steam within the system until it's released for milk frothing. This helps maintain the temperature and pressure of the steam, which is crucial for creating the right texture in milk-based drinks.

4. Prevention of Cross-Contamination: By creating tight seals, O-rings help prevent the mixing of different fluids within the machine. For example, they can help keep used coffee grounds from entering the clean water system.

5. Vibration Dampening: In some cases, O-rings also serve to dampen vibrations between different parts of the machine. This can help reduce noise and wear on components.

6. Temperature Regulation: O-rings help maintain the intended temperature of water and steam within different parts of the machine by preventing heat loss through gaps or connections.

The effectiveness of O-rings in performing these functions relies on their proper installation and maintenance. Over time, O-rings can degrade due to heat, pressure, and chemical exposure from coffee oils and cleaning products. Regular inspection and replacement of O-rings are essential to ensure the continued proper operation of the coffee machine.

4. O-rings and machine performance

The presence and condition of Coffee Machine O Rings have a significant impact on the overall performance and longevity of coffee machines. Properly functioning O-rings contribute to machine performance in several key ways:

1. Extraction Quality: By maintaining proper pressure and ensuring even water distribution, O-rings play a crucial role in achieving consistent extraction. This directly affects the flavor and quality of the coffee produced. In espresso machines, for instance, a failing O-ring in the portafilter can lead to "channeling," where water finds an easy path through the coffee puck, resulting in under-extraction and poor flavor.

2. Energy Efficiency: O-rings help maintain the intended pressure and temperature within the machine. When they function correctly, less energy is wasted in compensating for leaks or pressure loss, making the machine more energy-efficient.

3. Consistency: Properly sealed components ensure that the machine performs consistently from one brew to the next. This is particularly important in commercial settings where reproducibility is key to customer satisfaction.

4. Machine Longevity: By preventing leaks and maintaining proper pressure, O-rings help protect sensitive internal components from water damage and excessive wear. This can significantly extend the life of the coffee machine.

5. Safety: In machines that operate under high pressure and temperature, O-rings play a crucial role in ensuring safe operation. Failing O-rings could potentially lead to dangerous situations involving hot water or steam leaks.

6. Maintenance Needs: Well-maintained O-rings can reduce the frequency and extent of repairs needed. Conversely, neglecting O-ring maintenance can lead to more frequent breakdowns and potentially costly repairs.

Regular inspection and replacement of O-rings are essential for maintaining optimal machine performance. Signs that O-rings may need replacement include visible wear or damage, loss of elasticity, or the presence of leaks. Many coffee machine manufacturers recommend replacing O-rings as part of routine maintenance, typically annually or every few years, depending on usage.

It's worth noting that the quality of O-rings used can also impact machine performance. Using high-quality, food-grade O-rings that are specifically designed for coffee machines can ensure better performance and longevity compared to generic alternatives.

5. Coffee Machine O Rings for sale

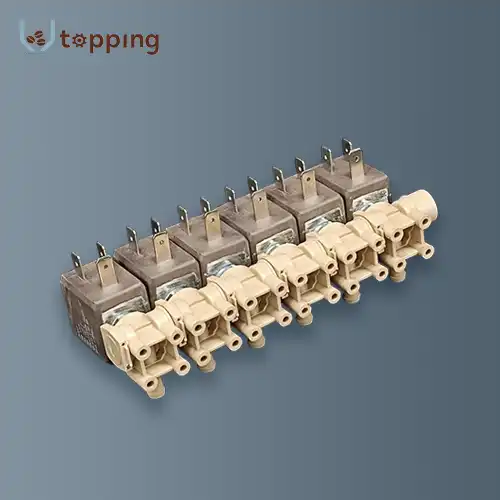

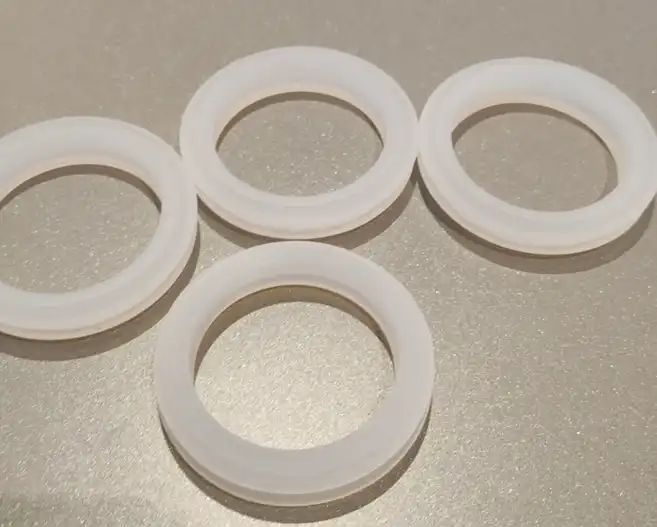

When it comes to maintaining or repairing coffee machines, having access to high-quality replacement O-rings is crucial. Topping Motor, a reputable manufacturer in the coffee industry, offers a range of Coffee Machine O Rings specifically designed for coffee machines. Their product line includes high-precision, small-size O-rings made from silicone rubber, which are particularly suited for the demanding conditions found in coffee equipment.

The use of silicone rubber in these O-rings is noteworthy. Silicone is an ideal material for coffee machine applications due to its excellent heat resistance, durability, and food-safe properties. It can withstand the high temperatures and pressures common in espresso machines while maintaining its elasticity and sealing properties over time. Additionally, silicone is resistant to the oils and acids present in coffee, which can degrade other materials over time.

Topping Motor's focus on high precision in their O-ring production is crucial for coffee machine applications. The exact dimensions and tolerances of O-rings are critical to their function, as even small variations can lead to leaks or improper sealing. By offering high-precision O-rings, Topping Motor helps ensure that replacement parts will fit and function correctly in a wide range of coffee machine models.

For coffee shop owners, equipment technicians, or manufacturers looking to source high-quality O-rings for coffee machines, Topping Motor welcomes inquiries at inquiry@vendingmachinepart.com. When contacting them, it's advisable to have specific information about your requirements, such as the dimensions of the O-rings needed, the specific application within the coffee machine, and any particular material requirements or certifications needed.

In conclusion, O-rings are indeed necessary components in coffee machines, playing a vital role in their operation, performance, and longevity. From maintaining proper pressure and preventing leaks to ensuring consistent extraction and safe operation, these small but crucial parts are indispensable in the world of coffee making. Regular maintenance and timely replacement of O-rings with high-quality alternatives can help coffee enthusiasts and professionals alike ensure that their machines continue to produce excellent coffee for years to come.

References

1. Illy, A., & Viani, R. (2005). Espresso Coffee: The Science of Quality. Academic Press.

2. Schomer, D. (2019). Espresso Coffee: Professional Techniques. Espresso Vivace.

3. Parker O-Ring Handbook. (2018). Parker Hannifin Corporation.

4. Coffee Machine Manufacturers Association. (2023). Industry Standards for Coffee Machine Components.

5. Specialty Coffee Association. (2023). Equipment Standards.

Send Inquiry