- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Description

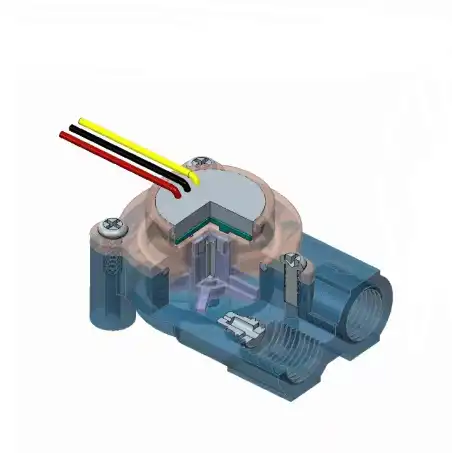

Flow Sensor Introduction:

A Flow Sensor is a basic part utilized in espresso machine assistants to exactly quantify the stream pace of fluids, like water, milk, or syrups. It assumes an imperative part in controlling the fermenting system, guaranteeing exact apportioning of fixings, and observing the exhibition of espresso machines. By identifying the progression of fluids progressively, Flow Sensor empower exact estimation, control, and enhancement of drink creation, prompting reliable quality and taste in some espresso.

Technical Specifications:

| Specification | Details |

|---|---|

| Flow Range | 0.1 to 10 liters per minute |

| Accuracy | ±1% to ±5% of reading |

| Operating Pressure | 0 to 10 bar |

| Fluid Compatibility | Water, Milk, Syrup |

| Operating Temperature | -20°C to 85°C |

| Material | Stainless Steel, Plastic |

| Output Signal | Digital, Analog |

| Power Supply | 5V DC, 12V DC, 24V DC |

| Connection Type | Threaded, Hose Barb, Quick Connect |

| Protection Rating | IP65 to IP68 |

| Certifications | CE, RoHS, NSF |

Performance Characteristics:

Flow Sensors are excellent coffee machine accessories due to a number of their performance characteristics:

High Accuracy: With exactness levels going from ±1% to ±5% of perusing, these sensors give exact estimation of fluid stream rates, guaranteeing consistency and repeatability in refreshment creation.

Wide Stream Range: With stream goes from 0.1 to 10 liters each moment, hall flow sensor can oblige different preparing cycles and drink volumes, from coffee shots to huge espresso servings.

Vigorous Construction: Developed from sturdy materials, for example, hardened steel and plastic, these sensors are impervious to erosion, scraped spot, and substance harm, guaranteeing long haul unwavering quality and execution.

Flexible Compatibility: Intended to work with a large number of liquids, including water, milk, and syrups, Stream Sensors are reasonable for different espresso recipes and menu choices.

Adaptable Result Options: These sensors can easily connect to coffee machine controllers, displays, and data logging systems, allowing for real-time monitoring and control. They are available with digital or analog output signals.

Versatile Mounting: Highlighting strung, hose point, or speedy interface associations, Stream Sensors can be effectively coordinated into espresso machine plans, working with establishment and support.

Natural Protection: With security appraisals going from IP65 to IP68, these sensors are impervious to residue, water, and natural pollutants, guaranteeing dependable execution in different working circumstances.

Working Principle:

The functioning guideline of a Flow Sensor includes the accompanying advances:

1. Liquid Flow: A sensing element or mechanism in the sensor experiences force as liquid moves through the flow path.

2. Detection: The sensor distinguishes this power and converts it into an electrical sign relative to the stream pace of the fluid.

3. Signal Processing: The electrical sign is handled by the sensor's gadgets to decide the stream rate and create a result signal.

4. Output: The result signal, either computerized or simple, is communicated to the espresso machine's control framework for additional handling and activity, for example, changing siphon speed or showing stream rate data.

Application Field:

Flow Sensors find broad applications in the field of espresso machine extras, including:

1. Coffee Machines: used to precisely control brewing parameters like shot volume and extraction time by measuring the flow of water during the extraction process.

2. Programmed Brewers: Coordinated into trickle espresso machines to control the progression of water through the fermenting container, upgrading espresso extraction and flavor.

3. Milk Foaming Systems: used in milk frothers to keep an eye on the amount of milk flowing through, resulting in consistent frothing and steaming for specialty coffee drinks.

4. Syrup Dispensing: Introduced in programmed espresso candy machines to apportion seasoned syrups into refreshments, upgrading customization choices for clients precisely.

5. Cleaning Cycles: Used to quantify the progression of cleaning arrangements during machine support and sterilization strategies, guaranteeing intensive cleaning and cleanliness.

Maintenance and Care:

Legitimate upkeep and care are fundamental to guarantee the life span and ideal execution of a product:

1. Normal Cleaning: Clean the water flow sensor and stream way consistently to eliminate any development of espresso oils, milk buildup, or different foreign substances that might influence exactness and execution.

2. Calibration: Intermittently align the sensor as indicated by producer suggestions to keep up with precision and dependability.

3. Inspection: Regularly examine the sensor for indications of harm, wear, or consumption, and supplant any ragged or harmed parts immediately.

4. Natural Considerations: Safeguard the sensor from openness to outrageous temperatures, dampness, and cruel synthetics that might debase execution or cause glitch.

5. Useful Testing: Direct customary useful tests to confirm the sensor's exactness and responsiveness, distinguishing any issues right on time for brief goal.

Customer Service:

Our obligation to uncommon client assistance incorporates:

Technical Assistance: Our group of educated specialists is accessible to give specialized help, investigating, and direction on choosing and introducing Stream Sensors.

Warranty on Product: We offer an exhaustive guarantee on all Stream Sensor items, guaranteeing consumer loyalty and inner serenity.

Quick Response: We focus on brief reaction times to client requests, guaranteeing productive correspondence and backing all through the buying system.

Customization Options: We offer customization administrations to meet explicit prerequisites and inclinations, including sensor configuration, yield sign, and network choices.

Why Choose Us:

1. Expertise in the Field: With long stretches of involvement with assembling and providing espresso machine frill, we have the information and mastery to convey top notch items custom-made to the espresso business' special requirements.

2. Quality Assurance: Our items go through thorough testing and quality control cycles to guarantee prevalent execution, dependability, and solidness.

3. Customization Capabilities: We offer an extensive variety of customization choices to meet individual client prerequisites, including sensor determinations, yield signals, and mounting choices.

4. Reach globally: With a worldwide circulation organization, we can productively serve clients around the world, guaranteeing opportune conveyance and backing.

5. Client Satisfaction: We are focused on giving extraordinary items and administrations that surpass client assumptions, encouraging long haul organizations and fulfillment.

Contact Us

Beating is a producer and provider with numerous long periods of creation experience in Flow Sensor, with food-grade guaranteed espresso machine frill, a full scope of items, adjustable, and complete endorsements. We support OEM, quick conveyance, and house to house transportation. On the off chance that you are intrigued, kindly reach us at sales@huan-tai.org.

Send Inquiry

.webp)