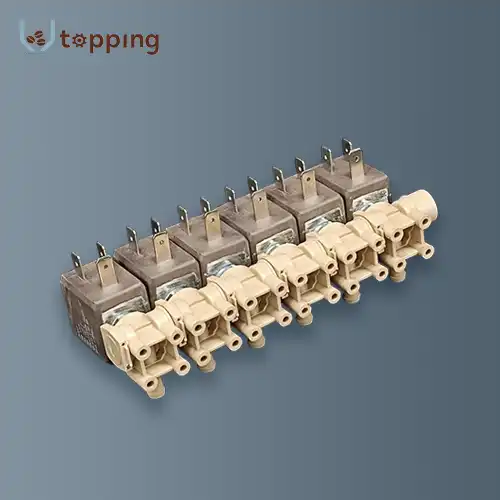

Submersible Water Pump

2. High efficiency and stable operation

3. It can be used by both water and land

4. Can be customized according to customer requirements

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Description

Submersible Water Pump Product Introduction

An essential component in the world of espresso machine frill is a Submersible Water Pump, which is designed to efficiently and consistently handle the water supply requests of both home-based and commercial espresso makers. Because they are made to work underwater, these pumps make sure that the water flows in coffee machines in a consistent and strong way. By maintaining constant water pressure and flow, it in the delivery of the precise amount of water required for brewing. The flavor and quality of the coffee are enhanced as a result.

Submersible Water Pump are recognized by their ability to work unobtrusively and actually, limiting the regular siphon activity commotion. This is especially crucial in cafes and restaurants, where a tranquil setting is essential.

Technical Specifications

| Specification | Details |

| Voltage | 12V 24V 36V DC |

| Frequency | 50/60 Hz |

| Power Consumption | 9-85W |

| Maximum Flow Rate | 1-30L/min |

| Maximum Head | 1-15 meters |

| Material | Food-grade ABS plastic |

| Operating Temperature Range | 0°C to 60°C |

| Cable Length | 1.5 meters |

| Dimensions | 125mm x 85mm x 65mm |

| Weight | 0.5 kg |

| Certification | CE, RoHS, FDA |

| Noise Level | <30 dB |

Performance Characteristics

Submersible Water Pump for espresso machines display a scope of execution qualities that make them undeniably appropriate for this application. Their plan and usefulness take care of the particular necessities of espresso machines, guaranteeing steady execution and high unwavering quality.

- Operation in Silence: Their quiet operation is one of the most important performance characteristics. These pumps are typically quieter than 30 dB, which keeps the atmosphere of coffee shops and home kitchens intact. Precision engineering and the use of high-quality sound-damping materials are the keys to this low noise level.

- Energy conservation: It is intended to be energy-proficient, drinking insignificant power while conveying ideal execution. These pumps are cost-effective to operate because they use around 20 watts of power, which is especially advantageous for commercial establishments where multiple units may be in use.

- High Pressure and Flow Rate: The coffee maker will always have access to a steady supply of water thanks to these pumps' high flow rate. The maximum head of two meters and maximum flow rate of up to 200 liters per hour guarantee that water can be delivered even in more complicated configurations.

- Construction that Lasts: They are built to withstand harsh operating conditions and are made of food-grade ABS plastic. The materials used resist wear and corrosion, ensuring a long lifespan. The sealed construction prevents water from entering, preventing damage to the internal components.

- Convenient and light: The minimized aspects and lightweight nature of these siphons make them simple to introduce in different espresso machine models. They can fit into tight spaces without sacrificing performance due to their small footprint.

- Resistance to Temperature: The fact that these pumps are able to function in temperatures ranging from 0°C to 60°C makes them suitable for a variety of settings and guarantees consistent performance regardless of the operating conditions.

- Certifications for safety: The FDA, CE, and RoHS certifications that are included with it for coffee machines are crucial safety certifications. Users can rest assured knowing that the pumps meet international safety and quality standards thanks to these certifications.

- Reliability: Intended for nonstop activity, these siphons are profoundly solid. They are able to run for a long time without overheating or failing, ensuring that coffee machines are functional during peak times.

In a nutshell, the quiet operation, energy efficiency, high flow rate, durability, compact size, temperature resistance, safety, and dependability of Micro submersible water pump make them an ideal choice for coffee machines.

Working Principle

- Activation of the Power Supply: The pump receives power from the electrical supply when the coffee maker is turned on. The pump operates safely and effectively within the parameters that were designed thanks to the voltage and frequency specifications.

- Intake of Water: The pump's impeller begins to rotate as soon as it is activated. The impeller is a rotating part with blades that spin to produce a centrifugal force.

- Water Tension Development: As water keeps on streaming into the siphon, the diffusive power builds the water pressure. The water has to pass through the pump and out the discharge pipe because of this buildup of pressure.

- Water Expulsion: After that, the pump's outlet is used to release the pressurized water. The connection of this outlet to the water inlet of the coffee machine ensures a regulated and consistent supply of brewing water.

- Pressure Guideline: Pressure regulators and sensors are included in the equipment of many products. The water pressure is monitored and adjusted by these parts to keep it within the ideal range for brewing coffee. In order to extract the best flavor from the coffee grounds, this regulation is necessary to achieve the desired water flow rate and temperature.

- Automatic Deactivation: The shut-off mechanisms of some advanced products automated. These mechanisms kick in when the reservoir's water level falls below a predetermined threshold, preventing the pump from running dry and causing damage.

- Repetition of a Cycle: For as long as the coffee maker is in use, the entire procedure is repeated repeatedly. The pump keeps the coffee's consistency and quality intact by ensuring that there is always a sufficient supply of water.

This step-by-step procedure demonstrates the effectiveness and dependability of coffee machines' by ensuring a steady and controlled water supply, which is necessary for perfect coffee brewing.

Application Field

Several important areas of application include:

- Homegrown Espresso Machines: Submarine water siphons are broadly utilized in home espresso machines, including coffee creators, dribble espresso machines, and single-serve espresso brewers. They make sure that these machines always have water, which is important for making good coffee at home.

- Coffee Makers for Commercial Use: Commercial coffee machines are frequently used in hotels, restaurants, and cafes. Submarine water siphons in these machines give a solid water supply, supporting nonstop activity and high client turnover without settling on espresso quality.

- Dispensary Equipment: It is used in coffee vending machines, which can be found in offices, hospitals, and other public places.These siphons guarantee that the candy machines can apportion espresso and different refreshments effectively and rapidly.

- Dispensers for beverages: Aside from espresso, submarine water siphons are utilized in different refreshment distributors, including those for tea, hot cocoa, and other hot beverages. For the best beverage preparation, they aid in maintaining the required pressure and flow rate of water.

Maintenance and Care

Proper maintenance and care of Coffee machine booster pump are essential to ensure their longevity and optimal performance. Here are detailed steps for maintaining and caring for these pumps:

- Regular Inspection: Periodically inspect the pump for any visible signs of wear and tear, such as cracks, leaks, or corrosion. Regular inspections help identify potential issues early, preventing more severe damage.

- Cleaning the Pump: To maintain the pump’s efficiency, clean it regularly. Remove the pump from the water reservoir and disassemble it according to the manufacturer’s instructions. Clean all components, including the impeller and intake screen, using a soft brush and mild detergent. Rinse thoroughly with clean water before reassembling.

- Checking the Impeller: The impeller is a crucial component of the pump. Check it regularly for any signs of damage or wear. A damaged impeller can reduce the pump’s efficiency and cause it to fail. Replace the impeller if necessary.

- Inspecting Electrical Connections: Ensure that all electrical connections are secure and free from corrosion. Loose or corroded connections can cause the pump to malfunction. If any wires are damaged, replace them promptly.

- Lubricating Moving Parts: It requires periodic lubrication of moving parts to ensure smooth operation. Use only the recommended lubricant and follow the manufacturer’s guidelines for application.

Why Choose Us

Topping is a manufacturer and supplier with many years of production experience in Submersible Water Pump, with food-grade certified coffee machine accessories, a full range of coffee vending machine water pump, customizable, and complete certificates. We support OEM, fast delivery, and door-to-door transportation. If you are interested, please contact us at sales@huan-tai.org

Send Inquiry

.webp)