Differences Between Volumetric Counters And Particle Counters

2024-09-04 16:02:23

In the world of measurement and analysis, two important tools stand out: volumetric counters and particle counters. While both are used to quantify substances, they operate on different principles and serve distinct purposes. This blog post will explore the key differences between these two types of counters, their applications, limitations, and a spotlight on China's volumetric counter industry.

Principle

Volumetric counters and particle counters operate on fundamentally different principles. Volumetric counters, as the name suggests, measure the volume of a substance passing through them. They typically use mechanical or electronic means to track the amount of liquid or gas flowing through a system. These counters often employ mechanisms like rotating disks, pistons, or chambers that fill and empty in a precise manner to measure volume.

On the other hand, particle counters focus on detecting and counting individual particles suspended in a fluid or gas. They use various technologies such as light scattering, laser diffraction, or electrical sensing zones to identify and enumerate particles. As the sample passes through the counter, it detects each particle and categorizes them based on size or other properties.

The key distinction lies in what they measure: volumetric counters track the total amount of a substance, while particle counters focus on the number and characteristics of discrete particles within a sample.

Applications

Volumetric counters find widespread use in industries where precise measurement of fluid or gas volume is crucial. They are commonly employed in:

1. Water management: Measuring water consumption in residential and commercial settings.

2. Oil and gas industry: Monitoring fuel dispensing and production rates.

3. Chemical processing: Controlling the flow of reagents and products.

4. Food and beverage production: Ensuring accurate ingredient proportions.

5. Pharmaceutical manufacturing: Precise dosing of liquid medications.

Particle counters, conversely, are essential in applications where the concentration and size distribution of particles are important. Their applications include:

1. Clean room monitoring: Ensuring air quality in semiconductor manufacturing and pharmaceutical facilities.

2. Environmental monitoring: Measuring air pollution and particulate matter levels.

3. Water quality testing: Detecting contaminants in drinking water and industrial effluents.

4. Oil analysis: Identifying wear particles in lubricating oils for predictive maintenance.

5. Medical diagnostics: Counting blood cells or other biological particles.

The choice between volumetric and particle counters depends on whether the total quantity or the individual particle characteristics are more relevant to the specific application.

Limitations

While both types of counters are invaluable in their respective fields, they each have limitations that users should be aware of.

Volumetric counters may face challenges such as:

1. Accuracy at low flow rates: Some designs struggle to maintain precision when measuring small volumes.

2. Sensitivity to fluid properties: Viscosity and temperature changes can affect measurement accuracy.

3. Wear and tear: Mechanical parts may degrade over time, affecting performance.

4. Limited information: They provide only volume data, not details about the composition or quality of the substance.

Particle counters also have their own set of limitations:

1. Sample preparation: Many samples require dilution or other preparation steps before analysis.

2. Size limitations: Each particle counter has a specific size range it can accurately measure.

3. Coincidence error: At high concentrations, multiple particles may be counted as one.

4. Interpretation challenges: Results can be affected by factors like particle shape and refractive index.

5. Cost: High-end particle counters can be expensive, especially for multi-channel or high-resolution systems.

Understanding these limitations is crucial for selecting the appropriate counter for a given application and interpreting the results correctly.

China Volumetric Counter

China has emerged as a significant player in the manufacturing of volumetric counters.

These certifications are particularly important for volumetric counters used in sensitive applications such as food processing, pharmaceutical manufacturing, or water management. The FDA certification ensures that the counter meets the U.S. Food and Drug Administration's standards for food and drug-related applications, while RoHS certification guarantees compliance with the European Union's restrictions on hazardous substances in electrical and electronic equipment.

For those contemplating the acquisition of a volumetric counter from Topping Motor or any other reputable Chinese manufacturers, it is highly advisable to establish direct contact with the company in question. This approach ensures that you receive comprehensive and tailored information tailored specifically to your volumetric counter requirements. By doing so, you can gain a deeper understanding of the product's features, specifications, compatibility with your existing systems, and any unique advantages it offers over competitors.

Moreover, direct communication with the manufacturer opens up avenues for personalized support, including technical assistance, installation guidance, maintenance recommendations, and even customized solutions that might not be readily available on their website or promotional materials. Such personalized attention can be invaluable in ensuring the seamless integration and optimal performance of your volumetric counter within your operations.

Furthermore, engaging directly with the manufacturer can also provide valuable insights into their quality control processes, production capabilities, and after-sales service. These factors are crucial in assessing the reliability and longevity of the product, as well as the overall satisfaction you can expect from your investment.

In summary, while researching and comparing volumetric counters from various sources, including Topping Motor and other Chinese manufacturers, taking the extra step to reach out directly to the company can significantly enhance your decision-making process and ensure that you make an informed and satisfactory choice.

Interested parties can contact Topping Motor at sales@huan-tai.org to discuss their specific requirements and learn more about the available options.

In conclusion, while volumetric counters and particle counters serve different purposes and operate on distinct principles, both play crucial roles in various industries. Volumetric counters excel in measuring the quantity of fluids or gases, making them indispensable in applications requiring precise volume control. Particle counters, on the other hand, are essential for applications where the concentration and characteristics of individual particles are of primary concern. Understanding the differences, applications, and limitations of these counters is key to selecting the right tool for specific measurement needs. As the industry continues to evolve, with countries like China making significant contributions, users have access to a wider range of options to meet their precise measurement requirements.

References

1. Lipták, B. G. Instrument Engineers' Handbook, Volume One: Process Measurement and Analysis. CRC Press.

2. Jillavenkatesa, A., Dapkunas, S. J., & Lum, L. S. H. Particle size characterization. National Institute of Standards and Technology.

3. Baker, R. C. Flow measurement handbook: industrial designs, operating principles, performance, and applications. Cambridge University Press.

4. Kulkarni, P., Baron, P. A., & Willeke, K. (Eds.). Aerosol measurement: principles, techniques, and applications. John Wiley & Sons.

5. Wang, X., & McMurry, P. H. A design of a new condensation particle counter for atmospheric particle characterization. Journal of Aerosol Science.

Send Inquiry

Related Industry Knowledge

- How do vending machines' Refrigeration Unit keep products fresh?

- What Are the Benefits of Dual Boiler Coffee Machines?

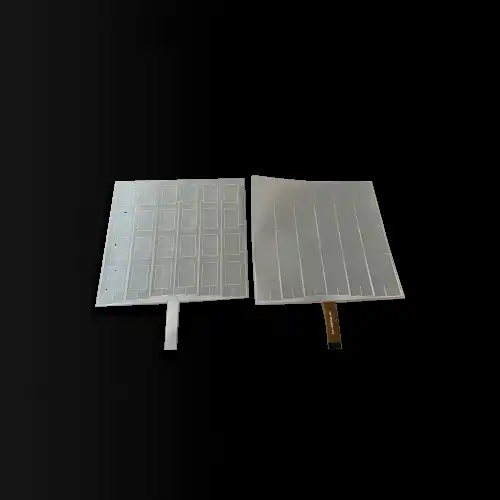

- What are the Specification parameters of vending machine touch screen?

- What Are the Key Components of a Coffee Vending Machine Dispensing System?

- How Do You Fix a Coffee Grinder Motor?

- Vending Machine Control Board Repair

- Coffee machine pump pressure

- How do you ensure the stability and durability of the vending machine board?

- Do coffee machines have built in grinder?

- What is a Vending Coffee Machine Water Tank?

.webp)

.webp)

.webp)