Why do we use volumetric counter?

2024-09-14 09:10:27

Volumetric counters play a crucial role in various industries, from pharmaceutical manufacturing to food processing. These precision instruments are designed to measure and dispense specific volumes of liquids or gases with high accuracy. As technology advances and industries demand greater precision, the use of the product has become increasingly prevalent. This article explores the key reasons why the product are essential in modern industrial processes.

Enhance precision and maintain uniformity

One of the fundamental and compelling reasons for adopting volumetric counters lies in their ability to substantially elevate the level of accuracy and consistency throughout the measurement process. For instance, an operator might misread a scale or make a miscalculation, which can consequently result in inconsistencies in product quality. In contrast, volumetric counters come to the rescue by offering precise and automated measurements without fail every single time.

For example, in drug production, the exact dosage of active ingredients is critical for patient safety and efficacy. They ensure that each batch of medication contains the correct amount of each component, maintaining consistent quality across production runs.

Moreover, volumetric counters can detect and account for variables that might affect measurement accuracy, such as temperature changes or pressure fluctuations.

Enhance production efficiency

Volumetric counters hold an extremely vital role when it comes to improving production efficiency, especially in the context of automated manufacturing processes. They contribute significantly to this goal. By seamlessly integrating these devices into production lines, companies are able to achieve remarkable results. Manual operations often lead to inconsistencies and slower processing times. Moreover, these counters help minimize downtime. Volumetric counters are designed to operate continuously and accurately, reducing the likelihood of breakdowns and ensuring a smooth flow of production.

In liquid distribution and packaging operations, volumetric counters enable rapid and accurate filling of containers. The speed and precision of the product allow for higher production rates while maintaining product quality.

Another example of volumetric counters enhancing efficiency is in the petrochemical industry. These devices are used to measure and control the flow of various fluids in refining processes, ensuring optimal mixing ratios and reducing waste. By automating these measurements, companies can operate their facilities more efficiently and with less human intervention.

Optimize resource use

Volumetric counters contribute significantly to resource optimization by enabling precise control over material usage.

In manufacturing processes that involve expensive or limited raw materials, accurate measurement is crucial to minimize waste. They allow for exact dispensing of ingredients, reducing overuse and ensuring that each product contains the optimal amount of each component. This precision not only saves money but also contributes to sustainability efforts by reducing unnecessary resource consumption.

Furthermore, volumetric counters help in managing inventory more effectively. By providing accurate data on material usage, these devices enable better forecasting and ordering of supplies, preventing both shortages and excess stock. This optimization of inventory management can lead to significant cost savings and improved cash flow for businesses.

Meet regulatory requirements

Volumetric counters play a crucial role in helping companies comply with these regulations and maintain high standards of quality and safety.

In the dynamic and tightly regulated food and beverage sector, where upholding the utmost standards of quality and honesty is imperative, precise ingredient measurement forms the bedrock. It not only ensures a consistent taste, texture, and overall excellence in the end product, catering to the increasingly discerning tastes of consumers, but also facilitates adherence to rigorous nutritional labeling mandates set forth by health regulatory bodies across the globe.

Volumetric counters, being an invaluable tool in this intricate process, offer an unparalleled level of precision and consistency that is vital for achieving uniformity across large-scale production runs. They operate by precisely measuring the volume of each ingredient, ensuring that every batch of product is formulated to the exact specifications, eliminating the possibility of under- or over-dosing of key components.

Moreover, the automation and precision offered by the product streamline production processes, reducing human error and enhancing overall efficiency. As manufacturers aim to fulfill the escalating consumer demand for healthier, tailored food and beverage options while preserving profitability, the significance of meticulous ingredient measurement becomes increasingly evident and crucial. Thus, investing in advanced volumetric countering technology is a strategic move that fosters product consistency, consumer trust, and regulatory compliance in today's highly competitive marketplace.

They help pharmaceutical companies maintain the exact specifications required for each medication, ensuring that every dose contains the correct amount of active ingredients. This precision is critical not only for regulatory compliance but also for patient safety and treatment efficacy.

Moreover, volumetric counters often come with features that support compliance efforts, such as data logging and traceability. These capabilities allow companies to maintain detailed records of their production processes, which is often a key requirement in regulated industries.

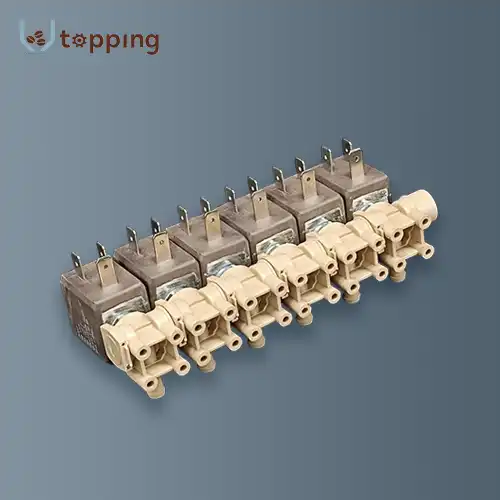

China Volumetric Counter

By assessing these aspects thoroughly, one can ensure that the selected manufacturer not only delivers reliable and durable equipment but also ensures compliance with industry regulations and offers timely and effective assistance when needed. One option to consider is Topping Motor Volumetric Counter, which boasts FDA and ROHS certifications.

These certifications are definitive proof that the products adhere to stringent safety and environmental standards. For companies operating in heavily regulated sectors or involved in international commerce with markets enforcing rigid requirements, these certifications are of paramount importance. They attest to the fact that the products have undergone extensive testing and rigorous assessment to guarantee their compliance with, or even surpassing, the established norms pertaining to consumer safety, health safeguards, and environmental conservation.

By possessing such certifications, companies can demonstrate their commitment to quality, sustainability, and ethical business practices. This not only bolsters consumer confidence in their products but also facilitates market access, as many importing countries require proof of compliance with specific safety and environmental standards before granting entry.

Moreover, these certifications can serve as a competitive advantage, differentiating products from those of less scrupulous competitors.

Thus, for companies aspiring to broaden their market reach, bolster their brand image, and remain compliant with the ever-changing regulatory landscape, acquiring and maintaining these certifications represents a strategic imperative. It is a cornerstone decision that underpins their efforts to grow and thrive in an increasingly competitive and regulated global marketplace.

When shopping for volumetric counters, it is advisable to explore a diverse range of options to identify the one that most effectively caters to your unique requirements and specifications. This approach ensures that you select the optimal solution tailored to your needs.If you're interested in learning more about Topping Motor's offerings, you can contact them at sales@huan-tai.org for further information and assistance.

References

1. Lipták, B. G. Instrument Engineers' Handbook, Volume One: Process Measurement and Analysis.

2. Spitzer, D. W. Flow Measurement: Practical Guides for Measurement and Control.

3. U.S. Food and Drug Administration. Current Good Manufacturing Practice (CGMP) Regulations.

Send Inquiry

Related Industry Knowledge

- Volumetric Counter For Coffee Machine

- How do you clean a coffee sieve?

- What Are the Benefits of Dual Boiler Coffee Machines?

- What Maintenance Does a Coffee Grinder Motor Require?

- How Do Dispensing Components Impact the Speed of Service in Vending Machines?

- What is a coffee dispenser?

- How much of a difference does a coffee grinder make?

- Is a built-in coffee grinder worth it?

- Is it necessary to have a Coffee Vending Machine Ingredient Canisters?

- What are the features of the Vending Machine Camera?

.webp)