How to deal with Vending machine cup dispenser empty?

2024-08-27 17:32:13

Restocking

Regular restocking is the most fundamental and crucial step in dealing with empty vending machine cup dispensers. This proactive approach ensures continuous service and customer satisfaction. Vending machine operators should establish a consistent schedule for checking and refilling cup dispensers based on the machine's usage patterns and location.

To implement an effective restocking routine, operators should first analyze the consumption rate of cups at each vending machine location. This can be done by keeping track of sales data and cup usage over time. High-traffic areas may require daily checks, while less frequented locations might need restocking only a few times a week. It's essential to consider peak usage times, such as lunch hours in office buildings or evenings in residential areas, to ensure adequate cup supply during these periods.

When restocking, it's important to follow proper handling procedures to maintain hygiene. Operators should wear clean gloves when handling cups and ensure that the cups are stored in a clean, dry environment before being loaded into the dispenser. It's also advisable to rotate stock, using older cups first to prevent any degradation in quality over time.

Some advanced vending machines come with built-in inventory management systems that can predict when restocking will be necessary based on historical data and current usage patterns. These systems can greatly improve efficiency by allowing operators to plan their restocking routes more effectively and reduce the likelihood of running out of cups.

Notify Maintenance Personnel

While regular restocking is crucial, there may be instances when a vending machine cup dispensers becomes empty unexpectedly. In such cases, quick notification of maintenance personnel is essential to minimize downtime and customer inconvenience. Establishing a clear and efficient notification system is key to addressing this issue promptly.

One effective approach is to implement a centralized reporting system. This could be a dedicated phone line, a mobile app, or a web portal where customers or on-site staff can report empty cup dispensers. The system should be designed to immediately alert the appropriate maintenance team or service personnel, providing them with essential information such as the machine's location, the specific issue (empty cup dispenser), and the time of the report.

To encourage reporting, vending machines should display clear instructions on how to notify maintenance personnel in case of any issues, including empty cup dispensers. This information could be prominently displayed on the machine itself or through digital displays if available. Some vending machines are equipped with a "report issue" button that customers can press to automatically send an alert to the maintenance team.

For larger vending operations, implementing a tiered response system can be beneficial. This system categorizes issues based on urgency, with an empty cup dispenser typically being a high-priority issue that requires immediate attention. This ensures that maintenance personnel can prioritize their tasks effectively, addressing critical issues like empty cup dispensers promptly to minimize service interruptions.

Maintenance And Cleaning

Regular maintenance and cleaning of vending machine cup dispensers are essential not only for hygiene but also for ensuring the smooth operation of the vending machine. When restocking cups, operators should take the opportunity to perform a thorough inspection and cleaning of the dispenser mechanism.

The maintenance routine should include checking all moving parts of the dispenser for signs of wear or damage. This includes examining springs, levers, and any electronic components that control the dispensing action. Any parts showing excessive wear should be repaired or replaced to prevent future malfunctions that could lead to empty dispensers or jammed cups.

Cleaning is equally important. The cup dispenser should be thoroughly sanitized to prevent the buildup of bacteria or mold that could contaminate the cups. This typically involves using food-safe disinfectants and following manufacturer-recommended cleaning procedures. Special attention should be paid to areas where cups come into contact with the dispenser mechanism.

It's also important to check and clean the area around the cup dispenser. Debris or spills can interfere with the proper functioning of the dispenser or create unsanitary conditions. Regular cleaning of this area helps maintain a positive image of the vending machine and encourages customer use.

Some modern vending machines are equipped with self-cleaning mechanisms or antimicrobial surfaces that help maintain hygiene between manual cleanings. However, these features should not replace regular maintenance and cleaning by operators, but rather complement these efforts to ensure the highest standards of cleanliness and functionality.

Automatic Monitoring System

Automatic monitoring systems represent a significant advancement in vending machine cup dispensers, offering a proactive solution to the problem of empty cup dispensers. These systems use sensors and connectivity to provide real-time information about the status of various vending machine components, including cup levels in the dispenser.

The core of these systems typically consists of level sensors installed in the cup dispenser. These sensors can be optical, mechanical, or weight-based, depending on the specific design of the dispenser. As cups are used, the sensors continuously monitor the remaining stock. When the number of cups falls below a predetermined threshold, the system triggers an alert.

These alerts are transmitted via cellular networks, Wi-Fi, or other Internet of Things (IoT) technologies to a central management system. This system can then automatically notify maintenance personnel through various channels such as SMS, email, or push notifications to a mobile app. Some advanced systems can even integrate with route planning software, allowing maintenance teams to optimize their restocking routes based on real-time data from multiple machines.

The benefits of automatic monitoring systems extend beyond preventing empty cup dispensers. They can also provide valuable data on cup usage patterns, helping operators optimize their restocking schedules and inventory management. By analyzing this data, operators can predict peak usage times, identify underperforming locations, and make informed decisions about vending machine placement and product offerings.

While the initial investment in automatic monitoring systems can be significant, many vending machine operators find that the long-term benefits in terms of increased efficiency, reduced downtime, and improved customer satisfaction more than justify the cost. As technology continues to advance, we can expect these systems to become even more sophisticated, potentially incorporating artificial intelligence to predict and prevent issues before they occur.

Vending Machine Cup Dispenser For Sale

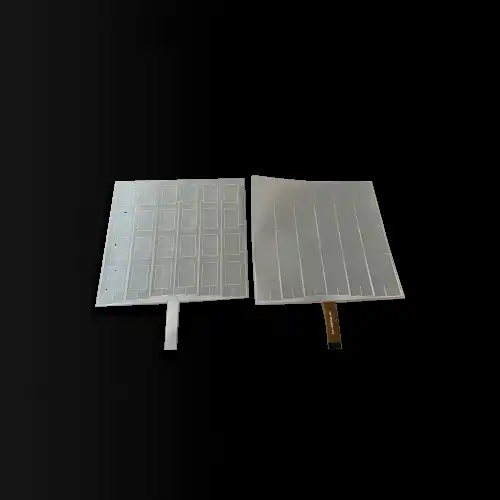

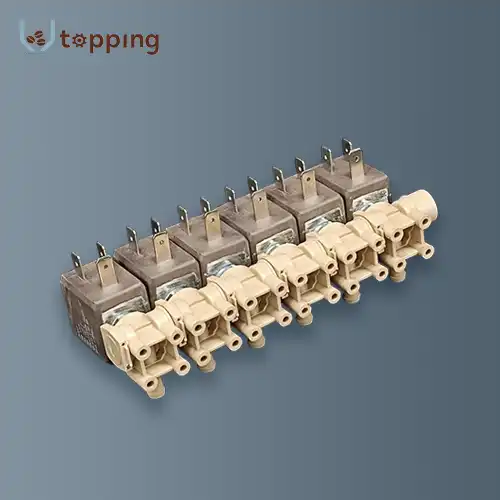

For vending machine operators looking to upgrade their equipment or expand their operations, choosing the right cup dispenser is crucial. Topping Motor offers vending machine cup dispensers that are designed to address many of the common issues associated with empty dispensers, including compatibility with multiple cup sizes.

The ability to accommodate various cup sizes in a single dispenser is particularly valuable for operators who offer a diverse range of beverages or who may need to adapt to changing customer preferences over time. This flexibility can help reduce the frequency of empty dispensers by allowing for larger cup capacities and easier restocking.

When selecting a cup dispenser, it's important to consider factors such as reliability, ease of maintenance, and compatibility with existing vending machines. The multiple size options offered by Topping Motor can help operators streamline their inventory management and reduce the complexity of machine maintenance.

For those interested in exploring Topping Motor's vending machine cup dispenser options or seeking advice on choosing the right dispenser for their needs, contacting sales@huan-tai.org is recommended. Their team can provide detailed information on available models, customization options, and how their dispensers can help address the challenge of empty cup dispensers effectively.

References

1. Journal of Food Service Management. (2023). "Optimizing Vending Machine Operations: Strategies for Preventing Empty Cup Dispensers."

2. International Journal of Retail & Distribution Management. (2022). "The Impact of IoT Technologies on Vending Machine Maintenance and Customer Satisfaction."

3. Food Control. (2023). "Hygiene Practices in Vending Machine Cup Dispensers: A Systematic Review."

4. Journal of Operations Management. (2022). "Predictive Maintenance in Vending Machines: A Case Study on Cup Dispenser Management."

Send Inquiry

Related Industry Knowledge

- How do vending machines' Refrigeration Unit keep products fresh?

- How Quickly Do Coffee Machine Boilers Heat Up?

- How can we ensure the control board for the vending machine follows industry standards?

- What Kind of Motor in Coffee Grinder?

- Are Coffee Grinder Motors Waterproof or Water-Resistant?

- Vending Machine Control Board Repair

- Do vending machines have cameras

- Coffee Sieve Sizes

- How Do You Clean a Plastic Coffee Hopper?

- What technologies does a vending machine with camera use?

.webp)