Vending Machine Cup Dispenser Mechanism

2024-09-09 16:51:13

Types of Cup Dispensers

Vending machine cup dispensers are essential components that ensure beverages are served in clean, individual containers. These dispensers come in various types, each designed to accommodate different cup sizes, materials, and vending machine configurations. The most common types include gravity-fed dispensers, spring-loaded dispensers, and carousel dispensers.

Gravity-fed dispensers are the simplest and most widely used type. They rely on the weight of the stacked cups to feed them into the dispensing mechanism. These dispensers are efficient for lightweight paper or plastic cups and are often used in high-volume vending machines. Spring-loaded dispensers use a spring mechanism to push cups downward, ensuring consistent dispensing even when the stack is low. This type is particularly useful for heavier cups or in situations where the machine may be subject to movement or vibration.

Carousel dispensers, also known as rotary dispensers, store cups in a circular arrangement. As cups are dispensed, the carousel rotates to present the next cup. This design is often used for machines that offer multiple cup sizes or types, as it can accommodate several different stacks of cups in a compact space. Some advanced vending machines may incorporate multiple dispenser types to handle various cup sizes and materials, providing flexibility in beverage options.

Cup Dispenser Mechanism Components

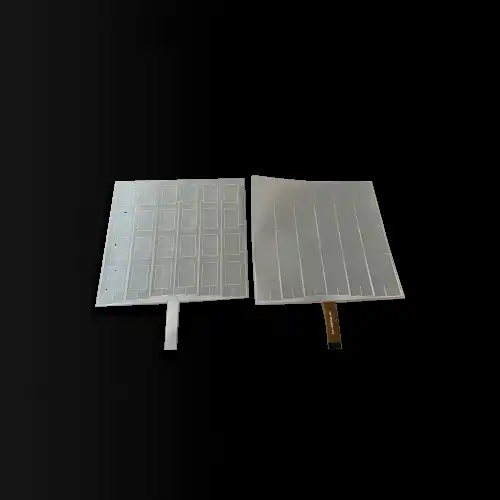

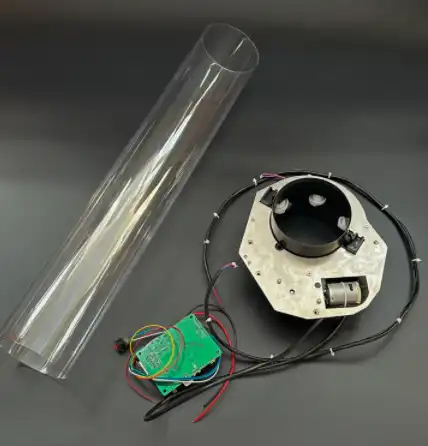

Vending machine cup dispenser consists of several key components that work together to ensure reliable and hygienic cup dispensing. The main components include the cup stack holder, separation mechanism, drop chute, and sensors. The cup stack holder is the storage area where cups are stacked and held in place until dispensing is required. It's designed to accommodate a specific cup size and shape, with some advanced models featuring adjustable holders for different cup types.

The separation mechanism is crucial for isolating a single cup from the stack. This typically involves a set of retractable fingers or a sliding plate that supports the stack while allowing the bottom cup to fall. The design of this component is critical to prevent double-dispensing or jams. The drop chute guides the dispensed cup to the filling area of the vending machine. It's often equipped with guides or baffles to ensure the cup lands in the correct position for filling.

Sensors play a vital role in the dispensing process. They detect when a cup has been successfully dispensed, monitor cup levels in the stack, and identify any jams or malfunctions. Modern vending machines often incorporate multiple sensors for enhanced reliability and performance. These may include optical sensors to detect cup presence and mechanical switches to confirm proper cup positioning.

How a Cup Dispenser Works?

Vending machine cup dispenser process in a vending machine is a carefully orchestrated sequence of events. When a customer initiates a beverage purchase, the vending machine's control system activates the cup dispenser. In a gravity-fed system, the weight of the cup stack presses down on the separation mechanism. The mechanism then retracts or shifts, allowing the bottom cup to fall while supporting the rest of the stack.

As the cup falls, it passes through the drop chute, which guides it to the proper position for filling. Sensors along the chute confirm that the cup has been successfully dispensed and is in place. If a cup fails to dispense or is not detected in the filling position, the machine will typically retry the dispensing process or alert the user to an error.

In spring-loaded systems, the process is similar, but the spring mechanism provides consistent pressure on the cup stack, ensuring reliable dispensing even when the stack is low. Carousel dispensers operate by rotating the appropriate cup stack into position before initiating the dispensing sequence. This allows for multiple cup types to be available in a single machine.

Once the cup is in place, the machine proceeds with the beverage preparation and filling process. After filling, some advanced machines may use additional mechanisms to move the filled cup to a pickup area, making room for the next dispensing cycle.

Factors Affecting Cup Dispenser Performance

Several factors can impact the performance and reliability of vending machine cup dispensers. Cup material and design are crucial considerations. Lightweight paper or plastic cups may require different dispensing mechanisms compared to heavier materials. The cup's shape, particularly the rim design, can affect how easily it separates from the stack.

Environmental factors also play a role in dispenser performance. Humidity can cause paper cups to stick together, while extreme temperatures may affect the properties of plastic cups or the dispensing mechanism itself. Proper ventilation and climate control within the vending machine can help mitigate these issues.

Maintenance and cleanliness are critical for consistent performance. Regular cleaning of the dispenser components prevents the buildup of debris that could interfere with cup separation or movement. Periodic inspection and adjustment of the separation mechanism ensure it continues to function correctly over time.

The frequency of use and restocking also affects dispenser performance. High-volume locations may require more frequent maintenance and component replacement. Proper loading of cups into the dispenser is essential; overfilling or misalignment can lead to jams or dispensing failures.

Advances in dispenser design have addressed many common issues. Some modern dispensers incorporate anti-static materials to prevent cups from sticking together. Others use air jets or vibration to assist in separating cups. Intelligent control systems can adapt to different cup types and environmental conditions, improving overall reliability.

Vending Machine Cup Dispenser for sale

When considering vending machine cup dispensers for purchase or upgrade, it's important to evaluate the specific needs of your vending operation. Topping Motor offers vending machine cup dispensers with compatibility for multiple cup sizes, providing flexibility for various beverage options. This versatility is particularly valuable for vending operators who serve a diverse range of drinks or who may need to adapt to changing customer preferences over time.

The ability to accommodate multiple cup sizes in a single dispenser can streamline inventory management and reduce the complexity of machine maintenance. It also allows vending operators to offer a wider variety of portion sizes, catering to different customer preferences or pricing strategies.

For those in the market for vending machine cup dispensers or looking to upgrade their existing equipment, it's crucial to consider factors such as reliability, ease of maintenance, and compatibility with your current vending machines. The team at Topping Motor can provide detailed information on their cup dispenser offerings and help determine the best solution for your specific needs. Interested parties can reach out to sales@huan-tai.org for more information on available models, customization options, and technical specifications.

References

1. Journal of Food Engineering. (2023). "Advances in Vending Machine Cup Dispenser Technology."

2. International Journal of Industrial Engineering. (2022). "Optimization of Cup Dispensing Mechanisms in Automated Beverage Systems."

3. IEEE Transactions on Automation Science and Engineering. (2023). "Sensor Integration in Modern Vending Machine Cup Dispensers."

4. Food and Bioproducts Processing. (2022). "Material Considerations in Vending Machine Cup Design and Dispensing."

5. Packaging Technology and Science. (2023). "Environmental Factors Affecting Vending Machine Cup Dispenser Performance."

6. Journal of Manufacturing Systems. (2022). "Reliability Analysis of Cup Dispensing Mechanisms in Beverage Vending Machines."

Send Inquiry

Related Industry Knowledge

- How does a Vending Coffee Machine Water Tank work?

- What are the specifications needed for the vending machine?

- Can Upgrading Your Coffee Grinder Motor Improve Grinding Consistency?

- How does a Vending Machine Spiral Motor work?

- What does a coffee sieve do?

- What Factors Influence Coffee Quality Through Ingredient Canisters?

- How Often Should You Refill Coffee Vending Machine Canisters?

- Do coffee vending machines need a Water Tank?

- How Long Can Coffee Beans Stay in the Hopper?

- Coffee Vending Machine Dispensing Components and Functions