What are Coffee Machine O Rings used for?

2024-12-16 11:25:47

Coffee Machine O Rings are intricate devices that rely on various components to function properly and produce high-quality coffee. Among these components, O-rings play a crucial yet often overlooked role. These small, circular seals are essential for the proper operation of coffee machines, particularly espresso machines. In this article, we'll explore the various uses of O-rings in coffee machines and why they are so important for coffee lovers and baristas alike.

Sealing

The primary function of O-rings in Coffee Machine O Rings is to create a watertight seal between different components. This sealing property is crucial for several reasons. First and foremost, it prevents leaks that could potentially damage the machine or create a mess on your countertop. More importantly, proper sealing is essential for maintaining the pressure required to brew high-quality espresso.

In an espresso machine, water needs to be forced through finely ground coffee at high pressure to extract the full flavor and create the characteristic crema. Any leak in the system would result in a loss of pressure, leading to under-extracted coffee and a subpar espresso shot. O-rings are strategically placed at various points in the machine where water or steam could potentially escape, such as between the portafilter and the group head, in the steam wand assembly, and around the boiler connections.

The effectiveness of O-rings in creating a seal depends on their material properties and correct installation. Most Coffee Machine O Rings O-rings are made from materials like silicone, EPDM (Ethylene Propylene Diene Monomer), or Viton, which can withstand high temperatures and pressure while remaining flexible enough to create a tight seal. When properly installed and maintained, these O-rings ensure that water and steam stay where they should, allowing the coffee machine to operate at peak efficiency.

Pressure

Pressure is a critical factor in espresso brewing, and O-rings play a vital role in maintaining the high pressure required for proper extraction. The ideal pressure for espresso extraction is typically between 9 to 10 bars, although some machines may operate at slightly different pressures depending on their design and the specific coffee being used.

O-rings contribute to pressure retention in several ways. In the group head, where the portafilter locks in place, O-rings ensure a tight seal that can withstand the high pressure of the brewing process. Without this seal, pressure would escape around the edges of the portafilter, resulting in uneven extraction and weak espresso.

Similarly, O-rings in the pump assembly and various valves throughout the machine help to maintain pressure as water moves through the system. These O-rings prevent pressure loss at connection points and ensure that the full force of the pump is directed towards the coffee grounds.

The ability of O-rings to maintain pressure under varying conditions is crucial for consistent espresso quality. As the machine heats up and cools down during use, materials expand and contract. O-rings are designed to maintain their sealing properties despite these temperature fluctuations, ensuring that pressure is retained throughout the brewing process.

Component Assembly

O-rings are integral to the assembly of various components in Coffee Machine O Rings. They act as gaskets between different parts, ensuring a proper fit and preventing any gaps that could lead to leaks. This role is particularly important in areas of the machine that are frequently disassembled for cleaning or maintenance, such as the group head and portafilter.

In the group head assembly, O-rings are used to create a seal between the shower screen, dispersion plate, and the group head itself. This ensures that water is evenly distributed over the coffee grounds during extraction. The portafilter also relies on O-rings to create a secure seal when locked into the group head, preventing leaks and ensuring that all water passes through the coffee grounds under pressure.

Steam and hot water valves are other areas where O-rings play a crucial role in assembly. These valves need to open and close smoothly while maintaining a watertight seal when closed. O-rings in these components ensure that steam and hot water are delivered on demand without any leaks or drips when the valves are shut.

The use of O-rings in component assembly allows for easier maintenance and repair of Coffee Machine O Rings. When a seal fails or a component needs to be replaced, it's often possible to replace just the O-ring rather than the entire assembly, saving time and money on repairs.

Preventing Corrosion

Corrosion is a significant concern in Coffee Machine O Rings due to the constant presence of water and high temperatures. O-rings play a crucial role in preventing corrosion by creating a barrier between metal parts that might otherwise come into direct contact with water or steam.

In areas where different metal components meet, such as between the boiler and connected pipes, O-rings not only provide a seal but also prevent metal-to-metal contact. This is important because when dissimilar metals come into contact in the presence of an electrolyte (in this case, water), galvanic corrosion can occur. By providing a non-metallic barrier, O-rings help to prevent this type of corrosion.

Additionally, by maintaining a watertight seal, O-rings prevent water from seeping into areas where it's not supposed to be. This is particularly important in electrical components or in areas where water could become trapped and lead to corrosion over time. By keeping water contained within the intended pathways of the machine, O-rings contribute significantly to the longevity of the Coffee Machine O Rings's internal components.

Safety

Safety is a paramount concern in the design and operation of Coffee Machine O Rings, and O-rings contribute significantly to this aspect. In many cases, O-rings are used to ensure that parts of the machine are securely fastened, which is particularly important in areas that get hot during operation.

For example, in the boiler assembly, O-rings help to secure heating elements and temperature sensors. A failure in these areas could lead to overheating or pressure buildup, potentially creating a safety hazard. By ensuring a secure fit, O-rings help to maintain the integrity of these critical components.

In steam wands and hot water dispensers, O-rings play a crucial role in preventing sudden releases of steam or hot water that could cause burns. They ensure that valves open and close properly, giving the user control over the flow of hot liquids and steam.

O-rings also contribute to electrical safety in coffee machines. By providing watertight seals around electrical components, they help to prevent water ingress that could lead to short circuits or electrical shocks. This is particularly important in areas where water and electricity are in close proximity, such as near pumps or control boards.

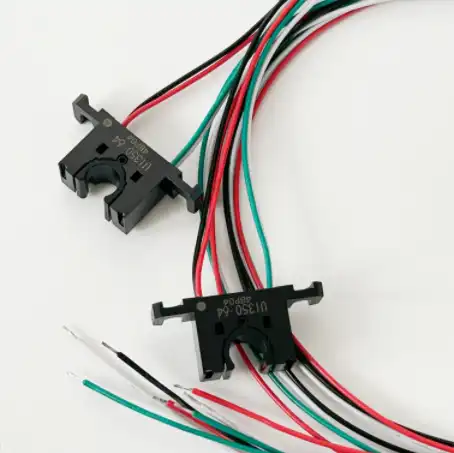

Coffee Machine O Rings for sale

When it comes to purchasing O-rings for coffee machines, it's crucial to choose high-quality components that can withstand the demanding conditions inside these devices. Topping Motor is a manufacturer that offers Coffee Machine O Rings designed to meet these challenges. Their O-rings are rated for a pressure range of 0 to 150 psi, making them suitable for most coffee machine applications, including espresso machines that typically operate at pressures around 130-145 psi (9-10 bars).

The wide pressure range of these O-rings ensures they can maintain their sealing properties under various conditions, from the low-pressure environment of a water reservoir to the high-pressure areas near the pump and group head. This versatility makes them suitable for use throughout the coffee machine, potentially simplifying maintenance and reducing the need for multiple types of O-rings.

If you're in the market for coffee machine O-rings or are a manufacturer looking for a reliable supplier, you can contact Topping Motor at inquiry@vendingmachinepart.com for more information about their products and how they might meet your specific needs.

References

1. Specialty Coffee Association. "The Science of Espresso Extraction."

2. Journal of Food Engineering. "Design Considerations for Modern Espresso Machines."

3. Apple Rubber Products Inc. "O-Ring Applications in Food and Beverage Equipment."

4. European Coffee Federation. "Coffee Machine Safety Standards."

5. Food and Drug Administration. "Regulations on Food Contact Substances in Beverage Preparation."

Send Inquiry

You may like