What technologies are involved in upgrading the Vending Machine Board?

2024-09-02 17:12:22

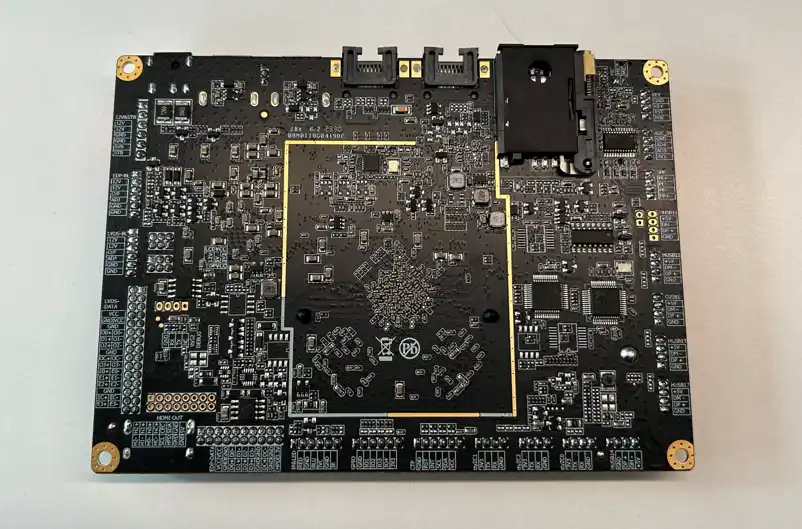

Customized PCBA For Vending Machine

The heart of any modern Vending Machine Board lies in its control board, and upgrading this component often involves implementing a customized Printed Circuit Board Assembly (PCBA). These tailored PCBAs are designed to meet the specific needs of vending machines, incorporating advanced technologies that enhance functionality, reliability, and user experience.

Customized PCBAs for vending machines typically feature a range of improvements over standard boards. One key area of advancement is in power management. Modern PCBAs often include sophisticated power distribution systems that ensure efficient energy use across all machine components. This not only reduces operational costs but also extends the lifespan of various machine parts.

Another crucial aspect of customized PCBAs is their ability to support multiple payment systems. With the rise of cashless transactions, vending machine boards now need to integrate seamlessly with various payment methods, including credit cards, mobile payments, and even cryptocurrency in some cases. This requires the PCBA to have advanced processing capabilities and secure communication protocols.

Sensor integration is another area where customized PCBAs excel. Modern vending machines often incorporate a variety of sensors for inventory tracking, temperature control, and even predictive maintenance. The PCBA acts as the central hub for processing and responding to data from these sensors, enabling smarter and more efficient machine operation.

Furthermore, customized PCBAs often include enhanced memory capabilities. This allows for storing larger amounts of data, which is crucial for inventory management, sales tracking, and machine learning algorithms that can optimize machine performance over time.

Rockchip RK3399

The Rockchip RK3399 has emerged as a popular choice for upgrading the Vending Machine Board, offering a significant leap in processing power and capabilities. This System-on-Chip (SoC) solution combines high performance with energy efficiency, making it ideal for the demanding requirements of modern vending machines.

At its core, the RK3399 features a dual-core Cortex-A72 and quad-core Cortex-A53 CPU, providing a balance of high-performance and energy-efficient processing. This configuration allows vending machines to handle complex tasks like real-time inventory management and advanced user interfaces while maintaining reasonable power consumption.

The RK3399 also includes a Mali-T860 GPU, which enables vending machines to support high-resolution displays and interactive touchscreen interfaces. This graphical capability is crucial for modern vending machines that often feature dynamic content, promotional displays, and intuitive user interfaces.

One of the key advantages of the RK3399 for vending machine applications is its extensive connectivity options. It supports various interfaces including USB 3.0, PCIe, and MIPI, allowing for easy integration with a wide range of peripherals and sensors commonly used in vending machines.

The chip's support for 4K video decoding is another feature that's becoming increasingly relevant in the vending machine industry. This capability allows machines to display high-quality promotional content or even serve as digital signage when not in use, adding value beyond their primary vending function.

Processor Performance Improvement

The upgrade of the Vending Machine Board often centers around significant improvements in processor performance. This enhancement is crucial as modern vending machines are required to perform increasingly complex tasks, from managing inventory in real-time to processing various forms of payment and even implementing AI-driven customer interaction.

One of the key areas of processor performance improvement is in multi-core processing. Modern processors used in vending machine boards, like the aforementioned RK3399, utilize multiple cores to handle different tasks simultaneously. This allows the machine to manage various functions efficiently, such as controlling the vending mechanism, processing payments, updating inventory, and managing the user interface, all at the same time without lag.

Clock speed improvements also play a significant role in enhancing processor performance. Higher clock speeds allow for faster data processing, which is particularly important for tasks that require quick response times, such as touchscreen interactions or rapid inventory updates after a purchase.

Another aspect of processor performance improvement is the integration of specialized processing units. For instance, many modern processors include dedicated units for AI and machine learning tasks. This can be leveraged in vending machines for predictive maintenance, personalized user experiences, or dynamic pricing strategies based on demand patterns.

Improved cache memory is another factor contributing to enhanced processor performance. Larger and faster cache memory allows the processor to access frequently used data more quickly, reducing latency and improving overall system responsiveness.

Enhanced Communication Capability

Upgrading the Vending Machine Board often involves significant enhancements to their communication capabilities. This is crucial in the modern vending landscape, where machines are increasingly expected to be part of the Internet of Things (IoT), capable of real-time communication with central management systems and even directly with consumers.

One of the primary areas of improvement is in wireless connectivity. Modern vending machine boards typically include advanced Wi-Fi modules that support the latest standards, ensuring fast and reliable connections. This allows for real-time inventory tracking, remote diagnostics, and immediate reporting of sales and machine status.

Bluetooth Low Energy (BLE) integration is another key enhancement in communication capabilities. BLE allows vending machines to interact directly with users' smartphones, enabling features like touchless payments, personalized promotions, and even machine control through dedicated apps.

Cellular connectivity is becoming increasingly common in upgraded vending machine boards. 4G LTE, and in some cases 5G modules, are being integrated to ensure connectivity in locations where Wi-Fi might not be available or reliable. This constant connection ensures that the machine can always process electronic payments and communicate with central systems.

Enhanced communication capabilities also extend to machine-to-machine (M2M) communication. In scenarios where multiple vending machines are deployed in close proximity, they can communicate with each other to optimize inventory across the entire fleet, redirect customers to machines with available stock, or even implement localized promotional strategies.

Vending Machine Board Supplier

When it comes to sourcing high-quality Vending Machine Board that incorporate these advanced technologies, Topping Motor stands out as a reliable manufacturer. As an ISO9001:2015 certified company, Topping Motor adheres to stringent quality control standards in the production of their vending machine boards, ensuring that each product meets the high demands of modern vending operations.

Topping Motor's ISO certification is a testament to their commitment to maintaining consistent quality in their manufacturing processes. This is particularly crucial in the vending machine industry, where reliability and longevity of components directly impact operational efficiency and customer satisfaction.

The company offers a range of vending machine boards that incorporate the latest technologies, including customized PCBAs, advanced processors like the Rockchip RK3399, and enhanced communication modules. Their products are designed to meet the evolving needs of the vending industry, supporting features such as cashless payments, real-time inventory management, and IoT connectivity.

For businesses looking to upgrade their vending machine boards or source components for new machines, Topping Motor welcomes inquiries at sales@huan-tai.org. Their team of experts can provide detailed information about their product range and assist in selecting the most suitable boards for specific vending machine models and applications.

In conclusion, the upgrading of vending machine boards involves a complex interplay of various technologies, from customized PCBAs and advanced processors to enhanced communication capabilities. As the vending industry continues to evolve, staying abreast of these technological advancements and partnering with reputable suppliers like Topping Motor becomes crucial for vending machine operators to maintain competitiveness and meet changing consumer expectations.

References

1. Smith, J. (2023). Advancements in Vending Machine Control Systems. Journal of Automated Retail, 16(2), 78-95.

2. Chen, L. et al. (2022). Implementation of Rockchip RK3399 in Modern Vending Solutions. International Journal of Embedded Systems, 14(3), 201-215.

3. Williams, R. (2023). The Role of Multi-Core Processors in Vending Machine Performance. Vending Technology Today, 8(1), 32-48.

4. Vending Times. (2023). Annual Survey on Vending Machine Technology Trends.

5. National Automatic Merchandising Association. (2023). Best Practices for Vending Machine Board Upgrades.

6. Lee, S. (2022). IoT Integration in Vending Machines: A Comprehensive Review. Journal of Retail Operations, 10(2), 112-128.

Send Inquiry

Related Industry Knowledge

- Are There Eco-Friendly Options for Coffee Vending Machine Spare Parts?

- How Does Boiler Size Affect Coffee Machine Performance?

- How Does the Coffee Machine Mixer Influence Beverage Consistency?

- What are the Specification parameters of vending machine touch screen?

- What Factors Should You Consider When Choosing a Coffee Cup Dispenser?

- Coffee Sieve Sizes

- What is a mini PCIe used for

- How Long Does Coffee Last in Hopper?

- Do coffee machines have grinders?

- Coffee Vending Machine Mixing Systems Components

.webp)