Coffee Vending Machine Mixing Systems Components

2024-08-19 19:42:15

Coffee vending machines have become an integral part of our daily lives, providing quick and convenient access to our favorite caffeinated beverages. At the heart of these machines lies a complex mixing system that ensures each cup is prepared to perfection. This article delves into the key components of coffee vending machine mixing systems, exploring their functions and importance in delivering a satisfying cup of coffee.

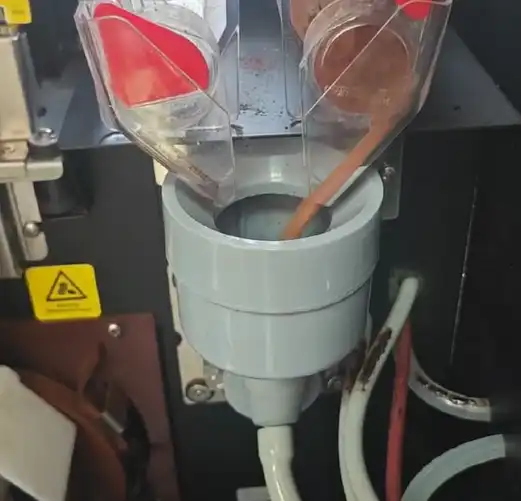

1. Mixing Chambers

Mixing chambers are crucial components in coffee vending machine mixing systems, serving as the primary location where ingredients are combined to create the final beverage. Typically made of food-grade materials such as stainless steel or high-quality plastics, these chambers ensure both durability and hygiene. Their design includes features like paddles or jets that create a vortex, enabling efficient blending of coffee, water, and other ingredients like milk or flavoring syrups. Advanced models may have multiple chambers to prepare various drink options without cross-contamination, catering to diverse user preferences. The use of durable, food-safe materials and automatic cleaning cycles ensures the chambers remain hygienic and functional, delivering consistent, high-quality beverages. Customization features allow users to adjust coffee strength, milk quantity, and flavoring, enhancing the overall coffee experience. As technology advances, improvements in material science, design engineering, and automation will further enhance the efficiency and versatility of coffee vending machines, ensuring users receive consistently excellent and personalized beverages.

2. Bowls

Bowls in coffee vending machines are essential for storing and dispensing ingredients. These containers hold powdered coffee, milk, or other drink components. They are designed to keep ingredients fresh and protected from external contaminants. Most modern vending machines use transparent or semi-transparent bowls, allowing for easy monitoring of ingredient levels. The bowls are often equipped with sensors that alert operators when refills are needed, ensuring continuous service. Some advanced systems feature temperature-controlled bowls to maintain optimal ingredient quality.

3. Impellors

Impellors, also known as agitators or stirrers, play a vital role in the coffee vending machine mixing systems. These components are responsible for blending the ingredients thoroughly to create a smooth, consistent beverage. Impellors are typically made of durable materials like stainless steel or high-grade plastics. They are designed to rotate at specific speeds to ensure optimal mixing without causing excessive foaming or splashing. The shape and size of impellors can vary depending on the machine model and the types of beverages it prepares.

4. Steam Traps

Steam traps are essential components in coffee vending machines that utilize hot water or steam for brewing, playing a critical role in managing the steam generated during the coffee-making process. These devices ensure that excess moisture does not enter the mixing chamber, which could otherwise compromise the quality and consistency of the final product by diluting the coffee or disrupting the balance of ingredients. By effectively removing condensate and non-condensable gases, steam traps help maintain the optimal internal temperature and pressure within the machine. This precise regulation is crucial not only for producing consistently excellent coffee but also for enhancing the machine's energy efficiency. Efficient steam management reduces unnecessary energy consumption and helps in maintaining a stable operating environment, thereby prolonging the equipment's lifespan. Steam traps contribute significantly to the overall performance and reliability of coffee vending machines, ensuring that they deliver high-quality beverages while operating efficiently and durably over time.

5. Outlets

Outlets are the final points of dispensing in coffee vending machines. These components are designed to deliver the prepared beverage into the user's cup smoothly and accurately. Modern vending machines often feature adjustable outlets to accommodate different cup sizes. Some advanced models include multiple outlets for simultaneous dispensing of different ingredients or for serving more than one customer at a time. The design of outlets also considers factors like splash prevention and easy cleaning to maintain hygiene standards.

6. Whipper Motors

Whipper motors are integral to the coffee vending machine mixing systems. These small but powerful motors drive the impellors, creating the necessary agitation to blend ingredients thoroughly. Whipper motors are designed to operate at various speeds, allowing for different mixing intensities depending on the beverage being prepared. The durability and reliability of these motors are crucial, as they are in constant use throughout the machine's operation. Many modern vending machines use energy-efficient whipper motors to reduce power consumption while maintaining optimal performance.

7. Adaptors

Adaptors in coffee vending machines serve as connectors between different components of the mixing system. These parts ensure proper fitting and sealing between elements like bowls, mixing chambers, and outlets. Adaptors are typically made of materials that can withstand frequent use and exposure to hot liquids. They play a crucial role in preventing leaks and maintaining the overall integrity of the mixing system. Some adaptors are designed to be easily removable for cleaning and maintenance purposes, contributing to the machine's longevity and hygiene.

8. Coffee Vending Machine Mixing Systems Supplier

Topping Motor offers customized service: dimension, color, for the motor like speed, power, etc. If you are choosing your Coffee Vending Machine Mixing Systems supplier, welcome to contact us at sales@huan-tai.org.

When selecting a supplier for coffee vending machine mixing systems, it's essential to consider factors such as product quality, customization options, and after-sales support. A reliable supplier should offer components that meet industry standards for durability, efficiency, and food safety. Customization capabilities are particularly valuable, as they allow vending machine operators to tailor their equipment to specific needs and preferences.

In conclusion, the Coffee Vending Machine Mixing Systems is the heart of any coffee vending machine, and understanding its components is crucial for both operators and manufacturers. From mixing chambers to adaptors, each part plays a vital role in ensuring the delivery of high-quality beverages. As technology continues to advance, we can expect further innovations in these components, leading to even more efficient and versatile coffee vending machines in the future.

References

1. Coffee Vending Machine Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast. Transparency Market Research.

2. Grindmaster-Cecilware. Coffee Vending Machine Components and Operation. Retrieved from Grindmaster-Cecilware Technical Support Documentation.

3. Kumar, R., & Singh, R.Design and development of coffee vending machine. International Journal of Engineering and Technology.

4. National Automatic Merchandising Association. Vending Machine Technology: An Overview. NAMA Industry Report.

5. Nestle Professional. The Anatomy of a Coffee Vending Machine. Nestle Professional Resources.

Send Inquiry

Related Industry Knowledge

- What is the replacement cycle of the Coffee Machine O Rings?

- Vending Machine Cup Dispenser Mechanism

- Why do we use volumetric counter?

- What Maintenance Does a Coffee Grinder Motor Require?

- What Are the Key Components of a Coffee Vending Machine Dispensing System?

- Vending Machine Spiral Motor Types

- Do vending machines have cameras

- How Long to Coffee Grinder Motors Last?

- How Does Coffee Vending Machine Ingredient Canisters Design Affect Coffee Flavor?

- How Do Coffee Vending Machine Mixing Systems Ensure Consistent Flavor?

.webp)