Why is Vending Coffee Machine Water Tank made of Food-grade plastic?

2024-10-17 10:26:14

Have you ever wondered why the tanks of vending coffee machines are made of food-grade plastic? This seemingly simple question opens up a fascinating world of materials science, food safety, and engineering that goes into every cup of vending machine coffee we enjoy.

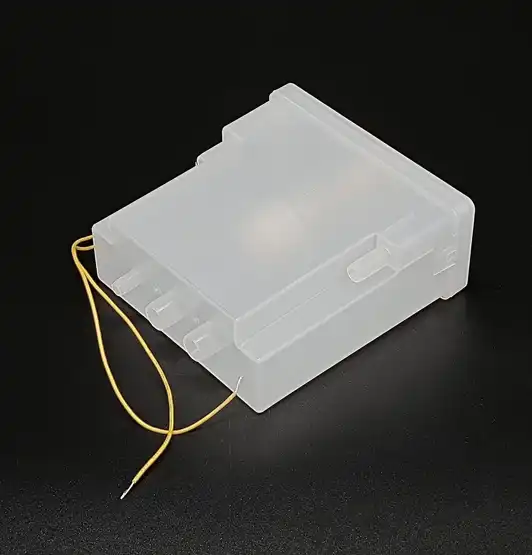

Food-grade plastics are specially formulated materials designed for safe contact with food and beverages. Because of their inert design, these plastics don't react with or contaminate the materials they come into contact with. In the context of vending coffee machines, the water tank is a critical component that directly interfaces with the water used to brew coffee. Therefore, the choice of material for this tank is of utmost importance.

The use of food-grade plastics in the vending coffee machine water tank is not just a matter of preference, but a carefully considered decision based on a combination of safety, durability, and functionality. Strict specifications must be met by these materials to guarantee that they don't leak dangerous chemicals into the water, that they don't harbor bacteria, that they can tolerate high temperatures, and that they keep their structural integrity through thousands of brew cycles.

Safety Regulations

The choice of food-grade plastics for a vending coffee machine water tank is governed by stringent safety regulations and standards designed to ensure consumer health and product integrity. In the United States, oversight by the Food and Drug Administration (FDA) is pivotal. Their Food Contact Substances program rigorously assesses the safety of materials intended for contact with food and beverages, setting clear guidelines for permissible use.

In the European Union, Regulation (EC) No 1935/2004 establishes a unified legal framework for food contact materials. This regulation mandates that materials do not transfer harmful constituents to food, alter its composition, or affect taste and odor. Materials like high-density polyethylene (HDPE) and polypropylene (PP), renowned for their chemical stability and resistance to leaching, are commonly employed in vending machine water tanks.

Durability also depends on the material's resistance to physical deterioration. To make sure they maintain safety standards and don't leak dangerous materials into drinks, even when exposed to high temperatures and extended contact, these plastics go through a rigorous testing process. Beyond safeguarding against chemical leaching, food-grade plastics act as effective barriers, preserving water quality from the initial filling to the final cup of freshly brewed coffee. This dual focus on safety and functionality underscores their crucial role in maintaining high standards of hygiene and consumer confidence.

Hygiene And Durability

The selection of food-grade plastic for the vending coffee machine water tank is driven by its superior hygiene and durability characteristics. These materials exhibit exceptional resistance to bacterial growth due to their non-porous, smooth surfaces, which prevent bacteria from adhering and proliferating. This inherent cleanliness ensures the water tank remains hygienic, contributing to the overall safety and quality of the dispensed beverages.

Food-grade polymers also boast remarkable durability in commercial settings, where hygiene is paramount. Their resistance to chemical breakdown enables them to withstand repeated exposure to cleaning solutions without deteriorating or releasing harmful compounds. This durability ensures the water tank maintains its integrity and performance over an extended period, reducing the frequency of replacements and minimizing maintenance costs.

Moreover, the chemical inertness of food-grade plastics preserves the original taste and quality of beverages. Unlike certain metals that can impart unwanted flavors or react with water over time, these plastics maintain beverage integrity, ensuring that every cup of coffee meets the desired taste profile and meets consumer expectations consistently. This combination of hygiene and durability makes food-grade plastic the ideal choice for the vending coffee machine water tank, safeguarding the health and satisfaction of consumers while ensuring the longevity and reliability of the equipment.

Heat Resistance

One of the most critical properties of food-grade plastics used in vending coffee machine water tanks is their heat resistance. Coffee brewing typically involves water temperatures between 195°F and 205°F (90°C to 96°C), and the water tank material must be able to withstand these temperatures without deforming or releasing harmful substances.

Food-grade plastics like high-density polyethylene (HDPE) and polypropylene (PP) have high heat deflection temperatures, meaning they maintain their structural integrity even when exposed to hot water. For instance, PP can typically withstand continuous use temperatures up to 212°F (100°C), making it suitable for coffee machine applications.

The heat resistance of these plastics is not just about maintaining shape. At a molecular level, the polymers in food-grade plastics are designed to remain stable at high temperatures. Because of its stability, the substance is kept from breaking down and releasing chemicals into the water, which may otherwise happen.

Moreover, food-grade polymers' thermal characteristics can improve vending machine energy efficiency. Certain polymers have strong insulating qualities, which lower the energy required to keep the water hot for brewing and aid in maintaining water temperature.

It's worth noting that while food-grade plastics are heat resistant, they're not indestructible. Extreme temperatures beyond their designed range can still cause damage. This is why proper maintenance and adherence to manufacturer guidelines are crucial for the longevity of vending machine water tanks.

Vending Coffee Machine Water Tank Manufacturers

In the competitive market of vending coffee machines, the selection of reliable water tanks is crucial. Leading manufacturers in the market, such as Topping Motor, are focused on producing premium water tanks made of food-grade plastic.

They exclusively utilize premium food-grade plastics that adhere to the highest safety standards, guaranteeing the purity of the water stored within.

For businesses seeking dependable vending coffee machine water tanks, Topping Motor stands as a trusted choice. Their knowledgeable team is available at sales@huan-tai.org to provide detailed product information and assist in selecting the ideal tank for specific machine requirements.

Every cup of coffee that is dispensed satisfies the highest requirements of safety and flavor thanks to the efficient and safe environment that these materials provide for the storage and heating of water. As technology and materials continue to advance, further enhancements in these critical components are eagerly anticipated.

References

1. Food and Drug Administration. (2023). "DFood Contact Substances (FCS)."

2. European Commission. (2022). "Food Contact Materials."

3. Journal of Food Science and Technology. (2024). "Safety Assessment of Food-Grade Plastics in Beverage Dispensing Systems."

4. Plastics Technology. (2023). "Food-Grade Plastics: Properties and Applications."

5. International Journal of Food Microbiology. (2022). "Bacterial Adhesion to Food Contact Surfaces."

Send Inquiry

Related Industry Knowledge

- What is the replacement cycle of the Coffee Machine O Rings?

- Touch screen for vending machine

- What Factors Should You Consider When Choosing a Coffee Cup Dispenser?

- How to Clean Coffee Grinder Motor?

- How to evaluate the performance and stability of the Control Board For Vending Machine?

- How Long to Coffee Grinder Motors Last?

- What is a Coffee Machine Pump?

- How Do Mixing Systems Impact the Efficiency of Coffee Vending Machines?"

- Can Coffee Beans Be Stored in a Grinder Hopper?

- Do coffee vending machines need a Water Tank?

.webp)