Coffee Vending Machine Mixing Systems Features

2024-08-22 16:21:26

Coffee vending machines have become increasingly sophisticated, offering a wide variety of beverages to suit every taste. At the heart of these machines lies the mixing system, a crucial component that ensures each cup is prepared to perfection. This article explores the key features of coffee vending machine mixing systems, highlighting the innovations that make them efficient, hygienic, and user-friendly.

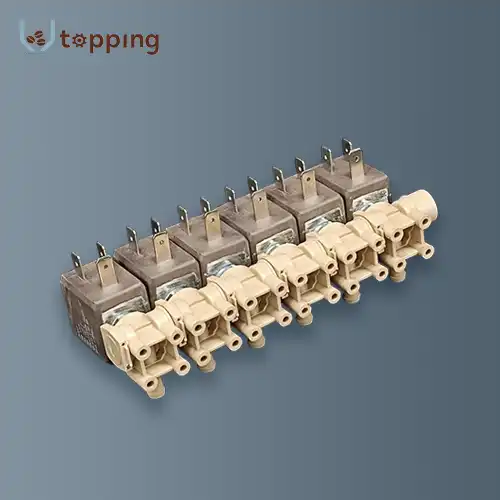

Food Grade Component

One of the most critical features of coffee vending machine mixing systems is the use of food-grade components. This aspect is paramount in ensuring the safety and quality of the beverages served. Food-grade materials are specially designed and manufactured to be safe for contact with food and beverages, meeting strict regulatory standards set by health authorities worldwide.

Typically, the components that come into direct contact with coffee, water, or other ingredients are made from high-quality stainless steel or food-safe plastics. Stainless steel is particularly favored for its durability, resistance to corrosion, and ease of cleaning. It doesn't impart any flavors to the beverages and can withstand the high temperatures involved in coffee brewing.

Food-grade plastics used in vending machines are BPA-free and designed to withstand repeated use without degrading or leaching chemicals into the beverages. These materials are also chosen for their ability to resist staining and odor retention, ensuring that each cup of coffee tastes fresh and free from any unwanted flavors.

The use of food-grade components extends beyond just the mixing chamber. It includes all parts of the system that come into contact with ingredients or the final product, such as tubes, nozzles, and dispensing spouts. This comprehensive approach to using food-safe materials demonstrates the industry's commitment to consumer health and safety.

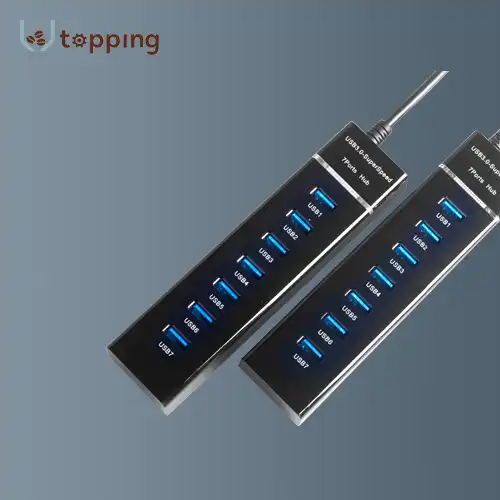

Compact Design

The compact design of coffee vending machine mixing systems is a testament to modern engineering and a response to the growing demand for space-efficient solutions. This feature is particularly important in environments where space is at a premium, such as office break rooms, hospital waiting areas, or busy transportation hubs.

Compact mixing systems are designed to maximize functionality while minimizing the overall footprint of the vending machine. This is achieved through clever engineering that integrates multiple components into a single, efficient unit. For example, the mixing chamber, whipper, and dispensing mechanism might be combined into one compact module.

The compact design also contributes to the machine's energy efficiency. With components placed closer together, there's less distance for ingredients and water to travel, reducing the energy required for pumping and heating. This not only lowers operating costs but also aligns with growing environmental concerns and sustainability initiatives.

Moreover, compact designs often translate to lighter machines, making them easier to transport and install. This is particularly beneficial for vending machine operators who need to move or replace units frequently. The reduced weight can also mean lower shipping costs and easier handling during maintenance procedures.

Simple To Fit and Easy to Clean and Maintain

The ease of fitting, removal, cleaning, and maintenance is a crucial feature of modern coffee vending machine mixing systems. This user-friendly approach not only simplifies operations for vending machine owners and technicians but also ensures consistent beverage quality and machine longevity.

Simplicity in fitting and removal is achieved through modular designs and tool-free assembly methods. Many modern mixing systems use quick-release mechanisms or snap-fit components that allow for rapid disassembly without the need for specialized tools. This design philosophy extends to all major parts of the mixing system, including the mixing chamber, impeller, and dispensing nozzles.

Easy cleaning is paramount in maintaining hygiene standards and preventing the build-up of coffee oils and residues that can affect taste. Many systems now incorporate smooth, non-porous surfaces that resist staining and are easy to wipe clean. Some advanced models even feature self-cleaning cycles that use hot water or steam to sanitize the mixing components automatically.

Maintenance simplicity is built into the design through easily accessible components and clear visual indicators for wear and tear. Some systems include diagnostic features that alert operators to potential issues before they become serious problems. This proactive approach to maintenance helps reduce downtime and extend the life of the machine.

The combination of these user-friendly features not only improves the day-to-day operation of the vending machine but also contributes to lower maintenance costs and higher customer satisfaction through consistently clean and well-functioning equipment.

Average grinding performance 260 gs

The grinding performance of a coffee vending machine is a critical factor in determining the quality and consistency of the beverages it produces. An average grinding performance of 2.60 grams per second (g/s) represents a significant advancement in vending machine technology, balancing speed with precision to deliver a superior coffee experience.

This level of grinding performance allows for rapid preparation of coffee drinks, which is essential in high-traffic locations where quick service is expected. At 2.60 g/s, a typical 7-gram dose of coffee for an espresso can be ground in just under 3 seconds, contributing to overall faster drink preparation times.

The consistency of the grind at this speed is crucial for extracting the full flavor potential of the coffee beans. Modern grinders in vending machines use precision-engineered burrs or blades that can maintain uniform particle size even at high speeds. This uniformity is essential for even extraction during the brewing process, resulting in a balanced and flavorful cup of coffee.

Advanced grinding systems also often incorporate features to prevent overheating of the coffee during the grinding process, which can negatively affect flavor. This might include temperature-controlled grinding chambers or intermittent grinding cycles for larger volumes.

The 2.60 g/s performance benchmark also reflects the machine's ability to handle a variety of coffee roasts and blends. From light to dark roasts, the grinder can adjust its operation to achieve optimal results for each type of coffee, ensuring versatility in the range of beverages offered.

Coffee Vending Machine Mixing Systems Supplier

Topping Motor offers customized service: dimension, color, for the motor like speed, power, etc. If you are choosing your Coffee Vending Machine Mixing Systems supplier, welcome to contact us at sales@huan-tai.org.

References

1. Automatic Merchandiser. The Evolution of Vending Machine Technology. Annual Industry Report.

2. European Vending Association. Hygiene and Food Safety in Vending Machines. EVA Guidelines.

3. Food and Drug Administration. Food Code 2021. U.S. Department of Health and Human Services.

4. International Vending Alliance. Global Trends in Vending Machine Design and Functionality. IVA Market Analysis.

5. Journal of Food Engineering. Advances in Coffee Grinding Technology for Vending Applications.

Send Inquiry

Related Industry Knowledge

- What is the replacement cycle of the Coffee Machine O Rings?

- How do vending machines' Refrigeration Unit keep products fresh?

- What Is a Single Boiler Coffee Machine?

- How Do Cup Dispenser Designs Impact User Convenience?

- How has the Vending Machine Camera technology developed over time?

- How does a Vending Machine Spiral Motor work?

- How to Clean Coffee Grinder Motor?

- How does a Coffee Machine Pump work?

- Is it necessary to have a Coffee Vending Machine Ingredient Canisters?

- How Do Mixing Systems Impact the Efficiency of Coffee Vending Machines?"

.webp)

.webp)