What safety standards and regulations need to be followed when designing vending machine circuit boards?

2024-09-14 14:16:25

Compliance With National Standards

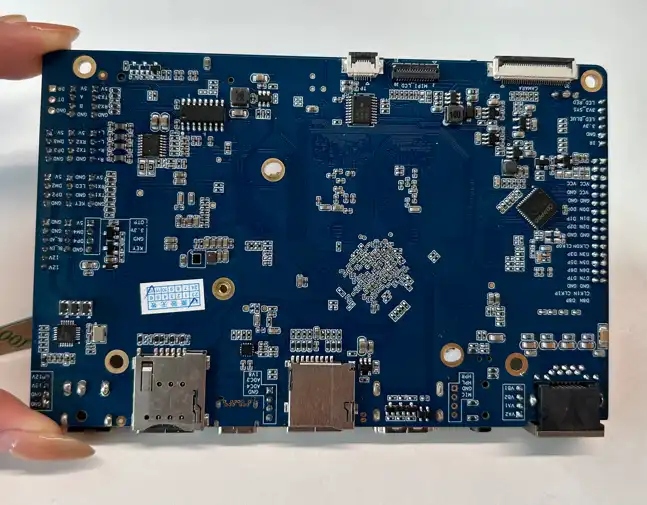

When designing Vending Machine Board circuit boards, adherence to national standards is paramount to ensure the safety and reliability of the machines. These standards provide a comprehensive framework that guides manufacturers in producing equipment that meets stringent safety requirements. In many countries, specific standards have been developed for vending machines, such as the Technical Requirements for Vending Machines.

One of the primary standards that vending machine circuit board designers must consider is electrical safety. This encompasses various aspects, including proper insulation, grounding, and protection against electrical shocks. For instance, the International Electrotechnical Commission (IEC) 60335-1 standard, which many national standards are based on, provides general requirements for the electrical safety of households and similar electrical appliances, including vending machines.

Another crucial area covered by national standards is electromagnetic compatibility (EMC). Vending machine circuit boards must be designed to operate without causing electromagnetic interference to other devices and to be resistant to interference from external sources. Standards such as IEC 61000 series provide guidelines for EMC testing and compliance.

Temperature management is another critical aspect addressed by national standards. Circuit boards must be designed to operate safely within specified temperature ranges, preventing overheating that could lead to component failure or pose fire risks. Standards often specify maximum operating temperatures and require thermal protection mechanisms.

Moreover, national standards often include requirements for the physical design of circuit boards. This can include specifications for PCB material quality, component spacing, and trace width to ensure durability and prevent short circuits. For example, the IPC-2221 Generic Standard on Printed Board Design provides guidelines that are often incorporated into national standards.

Product Compliance

Product compliance is a crucial aspect of Vending Machine Board design and manufacturing. It involves obtaining and maintaining various certificates that demonstrate adherence to safety standards and regulations. These certificates serve as tangible proof that the circuit boards and related components meet the necessary safety requirements.

One of the primary compliance certificates required is the electrical safety test certificate. This document verifies that the circuit board has undergone rigorous testing to ensure it operates safely under normal conditions and in foreseeable fault scenarios. Tests typically include dielectric strength tests, leakage current measurements, and temperature rise tests. In many regions, these tests are conducted according to standards like UL 751 in the United States or EN 60335-1 in Europe.

Material safety certificates are another critical component of product compliance. These certificates confirm that the materials used in the circuit board construction and its components are safe for their intended use. This is particularly important for vending machines that dispense food or beverages, as the materials must not leach harmful substances. Certificates may include RoHS (Restriction of Hazardous Substances) compliance, which restricts the use of certain hazardous materials in electrical and electronic equipment.

EMC compliance certificates are also essential. These documents verify that the circuit board meets electromagnetic compatibility standards, ensuring it doesn't produce electromagnetic interference that could affect other devices and is resistant to external electromagnetic disturbances. EMC testing is often conducted according to standards like FCC Part 15 in the US or EN 61000 series in Europe.

Additionally, some regions may require specific certifications for vending machine components. For instance, in the United States, the National Automatic Merchandising Association (NAMA) offers a certification program for vending machine components, which includes safety and performance testing.

Risk Assessment

Risk assessment is a critical process in the design and implementation of Vending Machine Board, especially when new formats, processes, or technologies are introduced. This is particularly important for vending machines that handle food or beverages, where food safety is paramount.

The risk assessment process typically begins with hazard identification. For vending machine circuit boards, this could include potential electrical hazards, thermal risks, or the possibility of chemical contamination from board materials. In the context of food vending machines, additional considerations might include the risk of microbial growth due to temperature control failures or cross-contamination risks from improper dispensing mechanisms.

Once hazards are identified, the next step is to evaluate the likelihood and severity of these risks. This involves considering factors such as the frequency of occurrence, the potential impact on consumer health, and the effectiveness of existing control measures. For instance, the risk of electrical shock might be considered high severity but low likelihood if proper insulation measures are in place.

Based on the risk assessment results, appropriate control measures should be implemented. These could include design modifications to the circuit board, such as adding redundant temperature sensors for critical food safety control points, or implementing fail-safe mechanisms that shut down the machine if certain parameters are exceeded.

For new technologies or processes, it may be necessary to conduct extensive testing and validation before implementation. This could involve accelerated life testing of components, stress testing under various environmental conditions, or even pilot deployments in controlled environments.

The results of these risk assessments and subsequent control measures should be thoroughly documented. This documentation forms the basis for obtaining necessary licenses and approvals from regulatory bodies. In many jurisdictions, food vending machines are subject to specific licensing requirements, and demonstrating a comprehensive risk assessment and management process is often a key part of obtaining these licenses.

Supervision And Inspection

Supervision and inspection play a crucial role in ensuring the ongoing safety and compliance of vending machine circuit boards, including their circuit boards. While initial design and manufacturing processes are important, continuous monitoring is essential to maintain safety standards throughout the operational life of the machine.

Market supervision and management departments typically conduct regular inspections of vending machines to ensure they continue to meet food safety standards. These inspections often include checks on the functionality of critical components controlled by the circuit board, such as temperature control systems, dispensing mechanisms, and payment systems.

Inspectors may use specialized equipment to test the electrical safety of the machine, checking for issues like current leakage or improper grounding. They may also verify that the machine's EMC characteristics have not degraded over time, which could happen due to component aging or environmental factors.

For food vending machines, inspections often include verifying that temperature control systems are functioning correctly. This might involve reviewing temperature logs stored in the machine's memory or conducting spot checks with calibrated thermometers. The circuit board's role in maintaining these critical food safety parameters is closely scrutinized.

Supervision also extends to ensuring that any software or firmware running on the circuit board is up-to-date and secure. With many modern vending machines connected to networks for inventory management and payment processing, cybersecurity has become an important aspect of vending machine safety.

In addition to scheduled inspections, many jurisdictions have systems in place for consumers to report issues with vending machines. These reports can trigger targeted inspections, allowing authorities to quickly identify and address potential safety issues.

Vending Machine Board Supplier

When it comes to sourcing circuit boards for vending machine circuit boards that meet these stringent safety standards and regulations, Topping Motor stands out as a reliable manufacturer. As an ISO9001:2015 certified company, Topping Motor demonstrates a commitment to quality management systems that ensure consistent production of high-quality components.

Topping Motor's ISO certification indicates that they have implemented robust processes for quality control, risk management, and continuous improvement. This is particularly important in the context of vending machine circuit boards, where reliability and safety are paramount.

The company's expertise in manufacturing vending machine boards means they are well-versed in the various national and international standards that apply to these components. Their products are designed and manufactured to meet electrical safety standards, EMC requirements, and other relevant regulations.

Topping Motor's commitment to quality extends to their selection of materials and components, ensuring that their circuit boards meet material safety requirements. This is crucial for vending machines, particularly those used in food and beverage dispensing, where material safety is a key consideration.

For businesses looking to source vending machine circuit boards that comply with all necessary safety standards and regulations, Topping Motor welcomes inquiries at sales@huan-tai.org. Their team can provide detailed information about their products' compliance with various standards and assist in selecting the most suitable boards for specific vending machine applications.

References

1. International Electrotechnical Commission. (2020). IEC 60335-1:2020 Household and similar electrical appliances - Safety - Part 1: General requirements.

2. National Automatic Merchandising Association. (2023). NAMA Certification Program.

3. U.S. Food and Drug Administration. (2022). Vending Machine Labeling Requirements.

4. European Committee for Standardization. (2021). EN 60335-1:2012+A2:2019 Household and similar electrical appliances - Safety - Part 1: General requirements.

5. Underwriters Laboratories. (2021). UL 751 Standard for Vending Machines.

6. International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements.

Send Inquiry

Related Industry Knowledge

- How does a Vending Coffee Machine Water Tank work?

- How do you clean a coffee sieve?

- How stable is Control Board For Vending Machine over different temperature and voltage ranges?

- What Is a Single Boiler Coffee Machine?

- What is a coffee brewing Unit Dimension ?

- How to Fix Coffee Grinder Motor?

- Coffee Sieve Sizes

- How Long Does Coffee Last in Hopper?

- What technologies are involved in upgrading the Vending Machine Board?

- How does the valve coffee machine work

.webp)