How does a Vending Machine Spiral Motor work?

2024-09-07 12:08:10

Snacks, drinks, and other products can now be purchased with ease and automation thanks to vending machines, which have changed the way we get them. At the core of many Vending Machine Spiral Motor lies a baffling part known as the screw engine, significant for guaranteeing proficient and solid apportioning of items.

Advancement of vending machine spiral motors

The idea of distributing traces all the way back to antiquated human advancements where components were utilized to apportion blessed water and different things.

In any case, current vending machine spiral motor as we probably are aware them started to arise in the mid twentieth 100 years.

These machines at first apportioned basic things like postcards and gum, developing over the long haul to offer a large number of items like bites, refreshments, and even gadgets.

How Vending Machines Work Vending machines work on a principle that is both straightforward and clever: they permit clients to make buys by embedding money or swiping cards, choosing an item, and getting the thing after installment.

A complicated mechanism that ensures the smooth and consistent completion of each transaction lies behind this seemingly straightforward procedure.

The Job of the Screw Engine

Fundamental to the usefulness of many vending machine spiral motors is the screw engine.

Because it makes it easier for products to move from their storage areas to the area where they will be delivered, this component is a crucial part of the dispensing procedure.

The process is as follows:

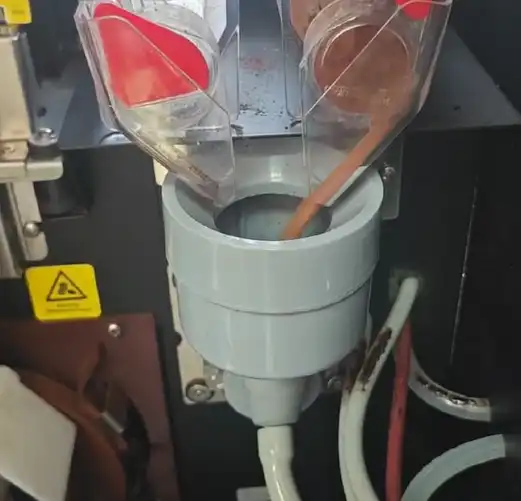

Mechanism for Product Dispensing: Inside a vending machine spiral motor, items are normally put away in compartments or plate. At the point when a determination is made by the client, the relating compartment is gotten to.

Screw Engine Activity: The screw engine is liable for pushing or pivoting a winding screw, which assists with pushing the item ahead toward the administering point. This action guarantees that the item selected will be delivered to the user in a timely manner without becoming stuck or jammed.

Reliability and precision: Screw motors are designed to function with accuracy and dependability. They are intended to deal with different sizes and states of items, guaranteeing that every thing is administered accurately like clockwork.

Designing Accomplishments and Developments

Throughout the long term, progressions in innovation have prompted critical enhancements in Vending Machine Spiral Motor.

The screw motor mechanism has always been improved by engineers to make it more effective, require less maintenance, and make the user experience better all around. These developments have made vending machine spiral motors an omnipresent presence out in the open spaces, workplaces, schools, and different areas around the world.

Keeping Customers Satisfied The screw motor's dependability has a direct impact on customer satisfaction.

Vending machines make it easier and more accessible for customers to access goods by ensuring that they are delivered promptly and accurately.

The effectiveness of theVending Machine Spiral Motor contributes to a positive experience whether a person is purchasing a beverage on the go or picking up a quick snack during a break.

Future Patterns

Looking forward, the development of vending machine spiral motors go on with headways in mechanical technology, man-made brainpower, and advanced installment frameworks.

These advancements are ready to make vending machine spiral motors much more natural and easy to understand. Despite its fundamental mechanical nature, the screw motor's function maintains the fundamental functionality of product dispensing, making it essential to these future developments.

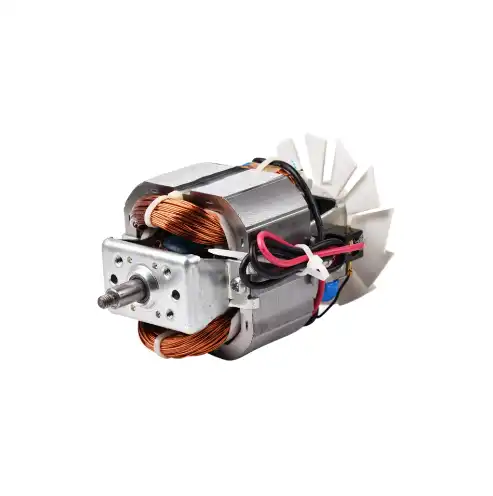

Motor Structure:

The screw engine, also known as a winding engine, has a simple but effective design that consists of two fundamental components: the stator and the rotor.

Coils of wire make up the stator, which is the motor's stationary component. Exactly when an electric stream flows through these circles, it delivers an alluring field.

This magnetic field interacts with the rotor, the motor's rotating component.

The screw motor has a spiral-shaped metal coil attached to the rotor as part of its distinctive design. As the rotor turns, the winding loop pivots, promoting items forward along the way of the curl. The vending machine's precise and controlled product dispensing depends on this rotary motion.

Working Principle:

The concepts of electromagnetic induction and the Lorentz force underpin the screw motor's operation.

An attractive field is created when an electric flow passes through the stator's loops.

The rotor pivots because of this attractive field's power on it.

The Lorentz force is the term used to describe the force felt by a conductor carrying current in a magnetic field.

As the rotor turns, the joined winding curl moves, changing over electrical energy into mechanical energy. This mechanical energy drives the twisting, which thus administers the item by pushing it forward. The product eventually reaches the coil's end and sinks into a collection tray, where the customer can retrieve it.

Control System:

A vending machine's control system is essential for controlling the screw motor's operation. To achieve precise motor control, modern vending machines use sophisticated control systems that incorporate sensors, microcontrollers, and software. Microcontrollers process this information and manage the motor's movements, while sensors determine the spiral coil's position and the presence of products.

At the point when a client makes a determination, the control framework initiates the fitting engine to pivot the twisting curl and administer the picked item. The software makes sure that the motor moves at the right speed and torque so that the product can be delivered accurately and reliably. Furthermore, a few frameworks use sensors to check that the item has been apportioned accurately and may change the engine's activity assuming that any issues are distinguished.

Torque and Speed:

The performance of Vending Machine Spiral Motor is significantly influenced by screw motor torque and speed characteristics.

Force alludes to the rotational power of the engine, while speed shows how rapidly the engine turns.

To ensure product delivery that is both effective and dependable, these characteristics must be carefully balanced.

Higher force is important to move heavier or bigger items, while quicker velocities can work on the general productivity of the distributing system. Be that as it may, exorbitant speed can prompt item sticks or harm. Subsequently, vending machine spiral motors are intended to streamline the force and speed of their screw engines to guarantee smooth and reliable activity.

Spiral Vending Machine Motor Manufacturers

Topping Motor has more than 10 years of experience in manufacturing Vending Machine Spiral Motors. With a large inventory and complete certifications, they are a reliable supplier for your vending machine needs. If you are looking for a Vending Machine Spiral Motor supplier, feel free to contact them at sales@huan-tai.org.

Send Inquiry

Related Industry Knowledge

- What is a volumetric counter?

- Can You Adjust the Boiler Temperature in Coffee Machines?

- How stable is Control Board For Vending Machine over different temperature and voltage ranges?

- What Innovations Are Improving Coffee Machine Mixer Technology?

- How Can You Adjust Mixer Settings for Different Coffee Blends?

- How to Fix Coffee Grinder Motor?

- Is there a difference between a coffee grinder and an espresso grinder?

- Is it necessary to have a Coffee Vending Machine Ingredient Canisters?

- What technologies are involved in upgrading the Vending Machine Board?

- What does a solenoid valve do in an espresso machine?

.webp)

.webp)