How do vending machine coin acceptor mechanical work?

2024-12-25 15:41:17

Vending Mechanical coin acceptors have been an essential component of vending machines for decades, serving as the primary means of accepting and validating currency. These devices, which are frequently overlooked, play a crucial role in ensuring the smooth operation of vending machines and customer satisfaction. They are made to precisely sort and validate products of various denominations while rejecting foreign or counterfeit currency.

The product works on the guideline of utilizing actual qualities of the products, for example, size weight and in some cases attractive properties to decide their legitimacy and worth Not at all like their electronic partners products don't expect power to work making them solid even in blackout circumstances This strength joined with their generally minimal expense has guaranteed their proceeded with use in many candy machines particularly in regions where power supply might be problematic.

The combination of carefully designed components and mechanisms enables these devices to process products quickly and efficiently, ensuring a smooth vending experience for users. Understanding how these mechanical marvels work can provide valuable insights into the world of vending machine technology and automated currency handling. Mechanical coin acceptors may appear simple at first glance, but they are actually intricate devices that rely on precise engineering to perform their function accurately.

Mechanical Structure

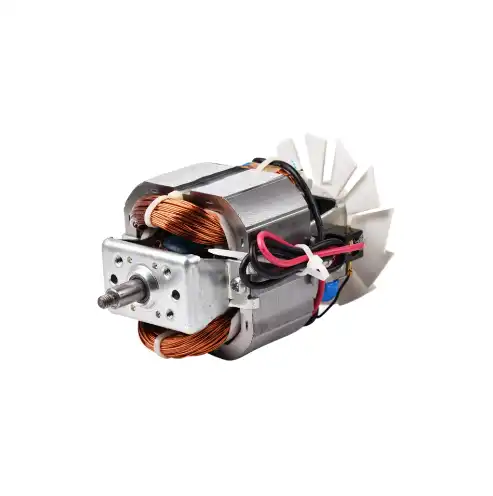

Vending Mechanical coin acceptors is a carefully designed system of levers, gears, and sensors that work together to accurately process products. Each component is important in the identification and authentication process, making sure that only valid products are accepted and counted correctly.

The product chute, which is typically a sloped path that directs the inserted the product through the various checking mechanisms, is the heart of the product. The angle of this chute is carefully calculated to control the speed of the product as it passes through the acceptor, ensuring that it is neither too fast nor too slow for accurate checking.

The products that are too large or too small will be deflected into a rejection chute and returned to the user. The gates are typically spring-loaded and calibrated to allow only products of the correct diameter to pass through. This initial sorting mechanism serves as the first line of defense against foreign or invalid currency. As the product travels down the chute, it encounters a series of gates and levers. These components are designed to sort products based on their size. The products that are too large or too small will be returned to

For products that pass the size check the subsequent stage frequently includes a progression of equilibrium components These can appear as turning arms or see-saw like designs that are aligned to tip at explicit loads As a product disregards these systems its weight makes them turn Assuming the weight falls inside the OK reach for a substantial product the instrument permits it to proceed on the off chance that not it is coordinated to the dismissal chute.

Some products likewise consolidate straightforward sensors regularly as mechanical switches or switches These can be utilized to count the quantity of acknowledged products or to set off different instruments inside the candy machine For example a switch may be moved by an acknowledged product flagging the machine to refresh the aggregate sum embedded.

They are able to process a wide range of product denominations quickly and accurately thanks to the precise arrangement and calibration of these components. The efficiency of this mechanical system is demonstrated by the fact that the entire procedure, from insertion to final acceptance or rejection, typically takes only a fraction of a second.

Authentication Process

Vending Mechanical coin acceptors is a basic step that goes past simple size and weight checking It includes a progression of components intended to confirm the credibility of products guaranteeing that fake or unfamiliar cash is dismissed This interaction depends on taking advantage of the one of a kind actual properties of real products.

One normal verification procedure utilized in products is attractive identification Numerous certified products particularly those of higher categories contain explicit attractive properties in view of their metal creation To distinguish these properties products frequently integrate magnets or attractive sensors into their plan As a product goes through the acceptor it communicates with these attractive components In the event that the connection matches the normal example for a veritable product it is permitted to continue On the off chance that not it is dismissed.

In some designs, a magnet is used to slightly slow down or deflect genuine products as they pass through the acceptor. Theproducts that don't behave as expected are deemed suspect and rejected. In more advanced systems, multiple magnets or sensors may be used to create a more comprehensive magnetic profile of the product.

Weight checking is one more significant part of the validation interaction While starting arranging could utilize a basic equilibrium instrument more exact weight registering can be integrated with the later phases of the products activity This could include an exceptionally adjusted support or stage that tips just when a product of the right weight is set upon it products that are too light or too weighty will bomb this check and be dismissed..

Some products likewise consolidate edge identification systems These can check for the presence of edges or other unmistakable edge includes that are normal for real products This is regularly finished through a progression of little distensions or sensors that the product should pass by As the product rolls past these components its edge communicates with them with a certain goal in mind Assuming the cooperation matches what is generally anticipated for a certifiable product it is acknowledged.

By relying on multiple physical properties of products, they are able to effectively screen out the majority of attempts at fraud while still processing valid products quickly and efficiently. This combination of these various authentication methods enables products to achieve a high degree of accuracy in detecting counterfeit or invalid currency.

Coin Counting

In Vending Mechanical coin acceptor machanical, this process is achieved through a combination of clever mechanical design and simple counting mechanisms. After a coin has successfully passed through the identification and authentication processes, the next crucial step is counting. This involves calculating the total value of the accepted coins and communicating this information to the vending machine.

The most fundamental type of product including in a mechanical acceptor includes the utilization of collectors These are regularly turning circles or wheels with scores or pits intended to hold currencies of explicit categories As mint pieces go through the acceptor they are coordinated into these gatherers Each time a currency enters it makes the aggregator pivot by one position This revolution can be utilized to monitor the quantity of currencies of every section that have been acknowledged.

In certain plans the collectors are associated with a progression of cog wheels or switches that make an interpretation of the rotational development into a straight development This direct development can then be utilized to drive a showcase component frequently as a mathematical counter noticeable to the client This considers a continuous update of the aggregate sum embedded giving prompt criticism to the client.

More refined products could utilize an arrangement of switches and cams to follow the worth of embedded products Each acknowledged product sets off a particular switch which thusly moves an including instrument The counting component may be a progression of cog wheels that pivot a showcase or it could include a more mind boggling arrangement of mechanical counters.

Some products utilize a credit switch framework In this plan each product category has its own switch When a product is acknowledged it pushes its relating switch The development of these switches is converted into an all out credit sum frequently showed through a window on the facade of the candy machine.

The counting component likewise needs to convey the complete worth to the candy machines control framework This is normally finished through a progression of mechanical switches or contacts As the count expands these switches are set off in a particular grouping permitting the candy machine to know when adequate installment has been gotten.

High Quality Vending Machine Coin Acceptor

Topping Motor has over 10 years of involvement and our item viable with different candy machines In the event that you are picking your Candy machine Coin Acceptor producers welcome to reach us at inquiry@vendingmachinepart.com.

References

1. Vending Times. (2023). "The Mechanics of Coin Acceptance: How Mechanical Coin Acceptors Work."

2. Journal of Mechanical Engineering. (2022). "Design and Analysis of Mechanical Coin Sorting Mechanisms in Vending Machines."

3. International Journal of Vending Technology. (2023). "Comparative Study of Mechanical and Electronic Coin Acceptors: Reliability and Efficiency."

Send Inquiry

.webp)