How stable is Control Board For Vending Machine over different temperature and voltage ranges?

2024-09-10 15:40:20

Temperature Stability

Vending machines, often found in diverse environments, require control boards that can withstand a wide range of temperatures. The stability of a control board for vending machines within a vending machine is paramount, as it ensures the machine's reliable operation regardless of external conditions. Typically, some products are designed to adapt to temperatures ranging from -20℃ to 70℃. This wide temperature range capability ensures that the vending machine remains functional in various climates, from the freezing winters to the scorching summers.

Moreover, intelligent temperature control systems are employed to further enhance the stability and performance of vending machines. These systems intelligently set, adjust, and monitor the internal temperature of the vending machine, optimizing the environment for the products being sold and improving overall sales performance. The implementation of such systems demonstrates a proactive approach to maintaining an ideal temperature for the goods, thereby reducing the risk of damage due to temperature fluctuations.

Voltage Stability

The voltage stability of a control board for vending machine is crucial for its uninterrupted operation. The products are often engineered to accommodate a broad voltage range, such as 12V to 36V. This design consideration allows the vending machine to function reliably under different power supply conditions, which can vary significantly depending on the location and power infrastructure.

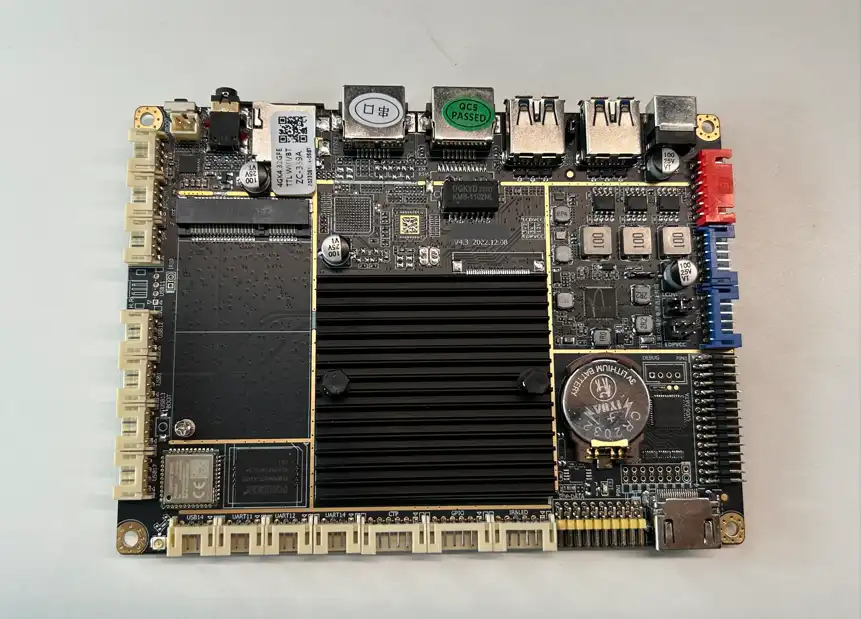

Industrial-grade motherboards used in vending machines are built to ensure stable communication networks and are resistant to moisture and high temperatures. These motherboards are designed with robustness in mind, ensuring that the product can operate effectively in challenging environments without compromising on performance or reliability.

Technical Implementation

Advanced electromagnetic optimization technology is integrated into some products to guarantee stable wireless device operation around the clock. This technology is vital for maintaining system stability and safety, as it minimizes the risk of communication failures that could impact the vending machine's functionality.

Furthermore, the technical solutions adopted by control board manufacturers may include innovative approaches to temperature management. For instance, using the external ambient temperature to supplement thermal interference can prevent unnecessary cooling or heating cycles. This not only improves the stability of the temperature control system but also enhances energy efficiency, contributing to the environmental sustainability of vending machines.

Environmental Adaptability

Vending machines have become ubiquitous in modern society, offering convenience and accessibility to a wide range of products including beverages, snacks, and even electronics. However, their deployment in diverse environmental settings poses challenges related to operational efficiency and longevity. The " Control Board For Vending Machine Environmental Adaptability" addresses these challenges by integrating advanced technologies and functionalities aimed at optimizing performance under varying environmental conditions.

Key Components and Features

- Temperature Control Mechanisms: The board incorporates temperature sensors and control mechanisms to regulate the internal temperature of the vending machine. This is critical in environments where temperatures can fluctuate significantly, such as outdoor locations exposed to direct sunlight or cold indoor environments like refrigerated spaces.

- Humidity Management: High humidity levels can impact electronic components and lead to malfunctions. The product includes humidity sensors and protective coatings to mitigate the effects of moisture, ensuring reliable operation over extended periods.

- Dust and Particle Filtration: Vending machines situated in outdoor or industrial settings are susceptible to dust and airborne particles. The product features filters and seals to prevent ingress, safeguarding internal components and preserving operational integrity.

- Water Resistance and Sealing: For vending machines installed in outdoor or semi-outdoor environments, waterproofing and sealing are crucial. The product incorporates water-resistant materials and seals around vulnerable areas such as dispensing mechanisms and electronic interfaces.

- Power Surge Protection: Electrical disturbances such as power surges or fluctuations can damage sensitive components within the vending machine. The product includes surge protection circuits and voltage regulators to stabilize incoming power and protect against transient spikes.

- Durability and Longevity Enhancements: Designed with robust materials and advanced manufacturing techniques, the product enhances the overall durability of the vending machine. This ensures a longer operational lifespan and reduces maintenance requirements, thereby lowering total cost of ownership.

Technological Integration

The "Board For Vending Machine Environmental Adaptability" leverages advancements in microelectronics and materials science to achieve optimal performance across diverse environmental conditions. Integrated circuits (ICs) with low power consumption and high thermal tolerance are employed to maximize efficiency without compromising reliability.

Case Studies and Real-World Applications

- Outdoor Vending Machines: In urban parks or transportation hubs where vending machines are exposed to sunlight and precipitation, the adaptability board ensures uninterrupted service by managing temperature fluctuations and protecting against water ingress.

- Refrigerated Vending Solutions: Within refrigerated compartments for perishable items, the board maintains consistent cooling temperatures and humidity levels to preserve product freshness and quality.

- Industrial Settings: Vending machines deployed in factories or warehouses benefit from dust filtration and ruggedized construction provided by the product, sustaining performance in harsh industrial environments.

Intelligent Control

Intelligent control systems in vending machines represent the convergence of technology and practical functionality. These systems can automatically switch between cooling and heating modes based on changes in the external ambient temperature. This capability ensures that the products within the vending machine are maintained within a certain set temperature range, optimizing the preservation of goods and ensuring customer satisfaction.

Control Board For Vending Machine Factory

Topping Motor, with over a decade of experience, exemplifies the industry standard for them. Their control boards for vending machines are designed to operate within a temperature range of -20℃ to 70℃, with a recommended optimal range of 5-35°C. The humidity requirements are set between 10% to 90%, with no condensation. For those seeking reliable control board manufacturers for vending machines, Topping Motor offers a trustworthy solution and can be contacted at sales@huan-tai.org for further inquiries.

References

[1] Information on the importance of stability in vending machine motherboards.

[2] Patent detailing an intelligent temperature control system for vending machines.

[3] Patent on a temperature control method and system for vending machines.

[4] Blog post discussing the design and implementation of motor control in vending machines.

Send Inquiry

Related Industry Knowledge

- How do you make coffee with a sieve?

- What is the difference between a filter and a coffee sieve?

- How Does Boiler Size Affect Coffee Machine Performance?

- How stable is Control Board For Vending Machine over different temperature and voltage ranges?

- Vending Machine Spiral Motor Types

- Coffee grounds sieve uses

- Do coffee machines have grinders?

- How Do Mixing Systems Impact the Efficiency of Coffee Vending Machines?"

- Can Coffee Beans Be Stored in a Grinder Hopper?

- What are the features of the Vending Machine Camera?

.webp)