Inside a Vending: What are the Different Parts of a Machine?

2024-10-10 09:49:04

Vending machines have become an integral part of our daily lives, offering convenience and accessibility to a wide range of products. These self-service machines are complex systems made up of various components working together seamlessly. In this article, we'll explore the different parts that make up a vending machine, focusing on key components such as the touchpad or keypad, bill acceptor, card acceptor, control board, and cooling and heating system. We'll also discuss the importance of choosing the right vending machine components manufacturer.

Touchpad Or Keypad

The touchpad or keypad is the primary interface between the user and the vending machine. It allows customers to input their selections and interact with the machine. Modern vending machines often feature touchscreens, while others still use traditional button-based keypads.

Touchpads typically use capacitive or resistive technology to detect user input. Capacitive touchscreens are more responsive and offer better clarity, but they can be more expensive. Resistive touchscreens are more durable and can be operated with gloves or styluses, making them suitable for outdoor environments.

Keypads, on the other hand, use a matrix of buttons connected to a microcontroller. When a button is pressed, it completes a circuit, sending a signal to the control board. Keypads are generally more robust and cost-effective, but they offer limited flexibility compared to touchscreens.

Regular maintenance of the touchpad or keypad is crucial to ensure proper functionality. This includes cleaning the surface to remove dirt and grime, and checking for any signs of wear or damage. In case of malfunction, the entire unit may need to be replaced to maintain the machine's usability.

Bill Acceptor

The bill acceptor, also known as a bill validator or bill reader, is a critical component of vending machines that accept paper currency. It's responsible for verifying the authenticity of inserted bills and determining their denomination.

Modern bill acceptors use a combination of optical and magnetic sensors to scan the bill as it's inserted. These sensors check for specific security features such as watermarks, security threads, and magnetic ink patterns. If the bill passes the validation process, it's accepted and stored in a secure cash box within the machine.

Key components of a bill acceptor include:

1. Bill transport mechanism: Guides the bill through the validation process

2. Optical sensors: Scan the visual elements of the bill

3. Magnetic sensors: Detect magnetic features in the bill's ink

4. Microprocessor: Analyzes the sensor data to determine bill authenticity and value

5. Cash box: Securely stores accepted bills

Regular maintenance of bill acceptors is essential to ensure reliable operation. This includes cleaning the bill path, sensors, and cash box, as well as updating the firmware to recognize new bill designs and security features.

Card Acceptor

As cashless payments become more prevalent, many vending machines now include card acceptors. These devices allow customers to pay using credit cards, debit cards, or contactless payment methods like mobile wallets.

Card acceptors typically consist of the following components:

1. Card reader: Reads the magnetic stripe or chip on the card

2. PIN pad: Allows customers to enter their PIN for debit transactions

3. Contactless reader: Enables tap-to-pay functionality for cards and mobile devices

4. Encryption module: Secures payment data during transmission

5. Communication module: Connects to payment networks for transaction processing

Card acceptors must comply with payment industry security standards, such as PCI DSS (Payment Card Industry Data Security Standard), to protect customer data. Regular software updates and security audits are necessary to maintain compliance and prevent fraud.

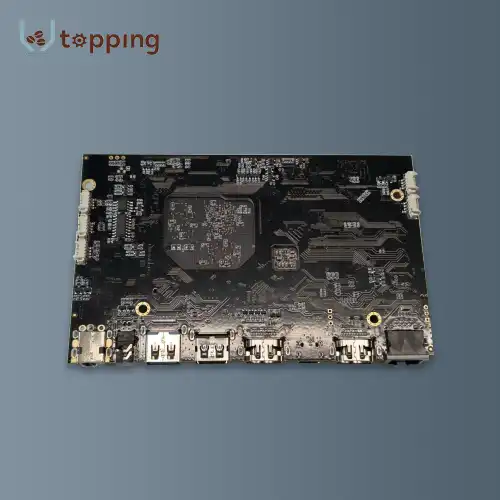

Control Board

The control board, or main circuit board, is the brain of the vending machine. It coordinates all the machine's functions, processes user inputs, and manages communication between various components.

Key functions of the control board include:

1. Processing user selections from the touchpad or keypad

2. Controlling the vending mechanism to dispense products

3. Managing payment transactions through bill and card acceptors 4. Monitoring inventory levels and machine status 5. Controlling temperature settings for refrigerated units 6. Communicating with remote management systems for reporting and maintenance

Control boards are typically custom-designed for specific vending machine models and may include various microcontrollers, memory chips, and communication interfaces. They often feature firmware that can be updated to add new features or fix bugs.

Troubleshooting control board issues requires specialized knowledge and tools. In many cases, if a control board fails, it's more cost-effective to replace the entire unit rather than attempt repairs.

Cooling And Heating System

Many vending machines, especially those dispensing perishable items or hot beverages, incorporate cooling and heating systems to maintain optimal product temperatures.

Cooling systems in refrigerated vending machines typically consist of:

1. Compressor: Circulates and pressurizes the refrigerant

2. Condenser: Releases heat from the refrigerant to the outside air

3. Evaporator: Absorbs heat from the inside of the machine, cooling the contents

4. Expansion valve: Regulates the flow of refrigerant 5. Thermostat: Monitors and controls the internal temperature

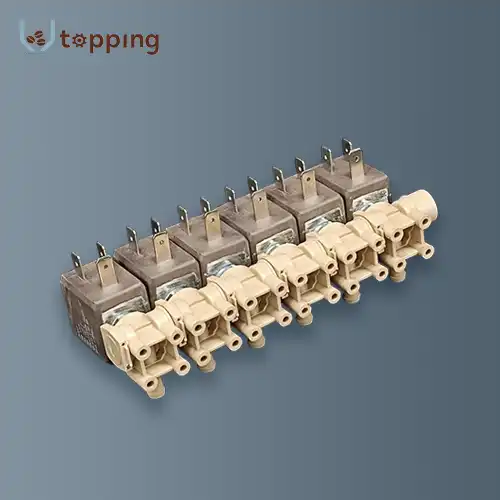

Heating systems, found in hot beverage vending machines, usually include:

1. Water tank: Stores and heats water for brewing

2. Heating element: Warms the water to the required temperature

3. Thermostat: Regulates water temperature

4. Pump: Circulates hot water through the brewing system

Regular maintenance of cooling and heating systems is crucial to ensure energy efficiency and product quality. This includes cleaning condenser coils, checking refrigerant levels, and descaling water heating components.

Vending Machine Components Manufacturer

Choosing the right manufacturer for vending machine components is crucial for ensuring the reliability and longevity of your machines. One such manufacturer is Topping Motor Vending Machine Components, which specializes in customized CNC parts and mechanical components for vending machines.

Topping Motor offers a range of high-quality, precision-engineered parts that can be tailored to specific vending machine models and requirements. Their use of advanced CNC technology ensures consistent quality and tight tolerances, which are essential for the smooth operation of vending machines.

When selecting a vending machine components manufacturer, consider factors such as:

1. Quality control processes

2. Customization capabilities

3. Compatibility with existing systems

4. Durability and reliability of parts

5. Technical support and after-sales service

6. Compliance with industry standards and regulations

For those in need of reliable vending machine components, Topping Motor welcomes inquiries at sales@huan-tai.org. Their expertise in manufacturing customized parts can help vending machine operators maintain and upgrade their equipment effectively.

References

1. Automatic Merchandiser. Vending Machine Technology: A Comprehensive Guide.

2. Crane Payment Innovations. Bill Validator Technology and Maintenance.

3. European Vending Association. Vending Machine Standards and Components.

4. Journal of Food Engineering. Thermal Management in Vending Machines: A Review.

5. National Automatic Merchandising Association. Best Practices for Vending Machine Maintenance.

Send Inquiry

Related Industry Knowledge

- What is the replacement cycle of the Coffee Machine O Rings?

- How often do you clean a Coffee Bean Hopper?

- What are the specifications needed for the vending machine?

- Can You Adjust the Boiler Temperature in Coffee Machines?

- What Are the Benefits of Dual Boiler Coffee Machines?

- Why is Cleaning the Coffee Machine Mixer Essential for Taste Quality?

- How Much Power Does a Coffee Grinder Use?

- How has the Vending Machine Camera technology developed over time?

- How does a Coffee Machine Pump work?

- What is Mini Pcie?

.webp)