What are the advantages of the Vending Machine Spiral Motor?

2024-09-26 17:52:52

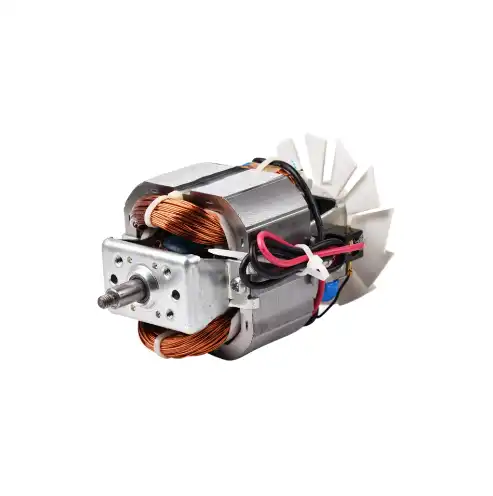

Vending machines are a ubiquitous part of modern life, providing convenient access to snacks, drinks, and other products. At the heart of many vending machines is the spiral motor, a crucial component that ensures the efficient delivery of goods. This article delves into the advantages of using spiral motors in vending machines, highlighting their key characteristics and benefits.

The vending machine spiral motor, also known as the helix motor, offers numerous advantages that enhance the overall functionality and efficiency of vending machines. By utilizing a precision-engineered spiral design, it smoothly guides products down the dispensing track with minimal jamming or misfeeds, enhancing customer satisfaction. Furthermore, its continuous rotation capability ensures swift and reliable service, even during peak usage hours. The spiral motor's durability and low-maintenance design contribute to reduced downtime and operational costs, making it a cost-effective solution for vending machine operators.

High Torque And Speed

One of the primary advantages of spiral motors in vending machines is their high torque and speed capabilities. These motors are designed to deliver the necessary power to rotate the spirals that dispense products. High torque ensures that even heavier items can be reliably dispensed without the motor stalling or struggling. The speed of the motor is also critical as it allows for quick delivery, enhancing customer satisfaction by reducing wait times. This combination of high torque and speed makes spiral motors ideal for handling a wide range of products with different weights and sizes efficiently.

The advantages of a high-torque and high-speed product can significantly enhance the performance and user experience of the vending machine. Here are some key benefits, organized into points:

- Efficient Product Dispensing: A high-torque motor ensures that products are smoothly and reliably dispensed from the vending machine. The increased torque allows the spiral shelf to overcome any resistance or jamming, resulting in a more efficient and consistent dispensing process.

- Reduced Jamming and Failures: The combination of high torque and speed reduces the likelihood of product jamming or the motor stalling during dispensing. This minimizes downtime for maintenance and repairs, ensuring continuous operation and customer satisfaction.

- Faster Transaction Times: A high-speed motor can quickly move products down the spiral track, reducing the wait time for customers. This enhances the overall user experience and encourages repeat purchases.

- Increased Capacity and Versatility: A powerful motor can handle a wider range of product sizes and weights, allowing the vending machine to offer a more diverse selection of items. Additionally, it may enable the machine to dispense multiple products simultaneously, further increasing its capacity and versatility.

- Longer Motor Lifespan: High-quality, high-torque motors are often designed for durability and reliability. They can withstand the demands of continuous operation, leading to a longer lifespan and reduced need for replacements.

- Lower Maintenance Costs: By reducing the frequency of jamming and failures, a high-torque and high-speed spiral motor can help lower maintenance costs over the vending machine's lifetime. This includes reduced downtime, fewer repairs, and potentially extended warranty periods.

- Improved Customer Satisfaction: Ultimately, the efficient and reliable operation of the product leads to improved customer satisfaction. Customers appreciate the quick and hassle-free transaction process, which can positively impact the machine's revenue and reputation.

Durability And Reliability

Strength and dependability are fundamental for any part utilized in vending machines, which are much of the time subject to ceaseless use and unforgiving circumstances. Spiral motors are worked to endure these requests. They are normally produced using top notch materials that oppose mileage, guaranteeing long haul activity without continuous upkeep or substitution. Their hearty development permits them to deal with high loads and work proficiently in different conditions, from cooled workplaces to outside areas with fluctuating temperatures and mugginess levels. This dependability guarantees that vending machines stay functional, limiting free time and upkeep costs.

The vending machine spiral motor, otherwise called the helix motor, assumes a crucial part in the effective activity of vending machines. Its durability and reliability offer several advantages that contribute to the overall performance and customer satisfaction of these automated retail systems. Here are some key advantages:

- Continuous Operation Capability: The spiral motor is designed for continuous duty cycles, allowing vending machines to operate 24/7 without interruption. This ensures that customers can access products at any time, enhancing convenience and satisfaction.

- Reduced Downtime: Due to its durability, the spiral motor minimizes the risk of breakdowns and unexpected downtime. This translates into increased uptime for the vending machine, maximizing revenue generation and minimizing maintenance costs.

- Efficient Product Dispensing: The spiral motor's precision and reliability ensure smooth and efficient product dispensing. It rotates the spiral shelf at a consistent speed, guiding products down the track without jamming or misalignments, leading to a seamless customer experience.

- Low Maintenance Requirements: High-quality spiral motors are built to last, requiring minimal maintenance over their lifespan. This not only saves on maintenance costs but also reduces the need for frequent service calls, ensuring the vending machine remains operational for longer periods.

- Increased Longevity: Durability and reliability contribute significantly to the overall longevity of the spiral motor. By withstanding the rigors of continuous use and resisting wear and tear, these motors can last for years, providing a cost-effective solution for vending machine operators.

- Enhanced Customer Trust: When vending machines consistently dispense products without issues, customers develop trust in the system. This trust encourages repeat purchases and can lead to increased customer loyalty and positive word-of-mouth referrals.

- Easy Replacement and Compatibility: While durability reduces the need for frequent replacements when the time comes, spiral motors are often designed for easy installation and compatibility with various vending machine models. This simplifies the replacement process and minimizes downtime.

Precise Control

Another significant advantage of spiral motors is their precise control capabilities. Vending machines require accurate and consistent delivery of products to ensure customer satisfaction and operational efficiency. Spiral motors can be precisely controlled using sensors and microcontrollers, allowing for exact positioning and movement of the spirals. This precision helps in accurately dispensing the correct product and quantity, reducing errors and preventing jams. Additionally, advanced control systems can adjust the motor's speed and torque based on the type of product being dispensed, further enhancing accuracy and efficiency.

The advantages of precise control in a Vending Machine Spiral Motor can significantly enhance the overall performance and user experience. Here are several key advantages:

- Efficient Product Dispensing: With precise control, the spiral motor ensures smooth and consistent movement of products down the dispensing track. This eliminates jamming, which can lead to customer frustration and machine downtime. By maintaining a steady flow of products, the machine operates more efficiently and reliably.

- Reduced Wear and Tear: Precise control also minimizes excessive forces on the motor and mechanical components. By operating within optimal parameters, the motor and associated parts experience less wear and tear, prolonging their lifespan and reducing maintenance costs.

- Increased Energy Efficiency: Efficient and precise motor operation translates to reduced energy consumption. This is especially important in vending machines, which are often powered by electricity and expected to operate continuously. By minimizing unnecessary energy usage, the machine becomes more environmentally friendly and cost-effective to operate.

- Enhanced User Experience: Customers appreciate the reliability and speed of a well-functioning vending machine. Precise control of the spiral motor contributes to a seamless purchasing process, where products are dispensed quickly and accurately. This enhances the overall user experience and encourages repeat purchases.

Energy Saving

Energy efficiency is an important consideration for vending machine operators looking to reduce operational costs and environmental impact. Spiral motors are designed with energy-saving features that optimize their performance while minimizing power consumption. By using efficient materials and designs, these motors convert electrical energy into mechanical energy more effectively, reducing energy loss. Additionally, the precise control systems can help manage energy use by adjusting the motor's operation based on real-time demand, ensuring that energy is used only when necessary. This not only lowers electricity bills but also contributes to more sustainable vending machine operations.

When it comes to energy saving, the vending machine spiral motor offers several advantages that contribute to a more efficient and eco-friendly operation. Here are some key points outlining these advantages:

Efficient Product Movement: The precise control of the spiral motor ensures smooth and efficient movement of products within the vending machine. This minimizes the energy required to dispense products, as the motor operates only as much as necessary to move items from the storage area to the dispensing slot.

Reduced Power Consumption: Efficient motor design and precise control mechanisms lead to reduced overall power consumption. This is particularly important in vending machines, which are often left running for extended periods, as it helps to minimize the environmental impact and reduce energy bills.

Low-Friction Components: Many modern products utilize low-friction materials and components. This not only improves the motor's lifespan but also reduces the amount of energy required to overcome friction during operation.

Dynamic Braking and Idle Control: Some advanced products incorporate dynamic braking and idle control systems. These features automatically adjust the motor's power output based on the current demand, ensuring that energy is not wasted when the motor is not actively dispensing products.

Spiral Vending Machine Motor Manufacturers

Topping Motor has more than 10 years of experience in manufacturing vending machine spiral motors. They offer a large inventory of high-quality motors, all with complete certifications. Topping Motor's products are known for their reliability, durability, and performance, making them a trusted supplier in the industry. If you are in the market for a product supplier, Topping Motor is a reputable option to consider. For more information, you can contact them at sales@huan-tai.org.

Send Inquiry

Related Industry Knowledge

- What are the precautions for maintenance Control Board For Vending Machine under extreme temperatures?

- What Safety Features Should You Look for in Coffee Machine Mixers?

- Why is Cleaning the Coffee Machine Mixer Essential for Taste Quality?

- How Do Cup Dispenser Designs Impact User Convenience?

- What is the coffee capacity of the coffee brewing Unit?

- What are the advantages of the Vending Machine Spiral Motor?

- How does a Vending Machine Spiral Motor work?

- What is a mini PCIe used for

- Vending machine board repair service

- How Long Can Coffee Beans Stay in the Hopper?

.webp)