What kind of motors do vending machines use?

2024-09-07 12:07:57

Have you ever pondered the reason why drinks and snacks magically appear in Vending Machine Spiral Motor? The response lies in the unpredictable apparatus taken cover behind the façade of these helpful containers.

At the center of every single treats machine are various kinds of motors that work as one to convey your optimal thing at the press of a button.

Vending machine spiral motor work on a somewhat basic guideline: they store items in coordinated compartments and utilize mechanical frameworks to apportion them when a client makes a determination. Notwithstanding, the execution of this rule includes modern designing, with engines assuming a urgent part all the while. These motors are in charge of a variety of tasks, such as turning product spirals, operating conveyor belts, and moving elevators that bring items to the area where they will be distributed.

Various kinds of vending machine spiral motors use different engine arrangements relying upon their plan and the items they apportion. Snack vending machines, for example, might use pump motors to dispense drinks, while beverage vending machines might use spiral motors to rotate the coils that hold individual items.However, one of the most common and adaptable motor types that can be found in modern vending machines is the screw vending machine motor, which is also known as a spiral motor.

Screw Vending Machine Motor

Vending Machine Spiral Motors are the workhorses of many bite and little thing vending machine spiral motors. These engines are intended to pivot winding loops that hold items, taking into consideration exact and controlled administering of things of different sizes and shapes. Screw motors are ideal for applications in vending machines due to their distinctive design and functionality.

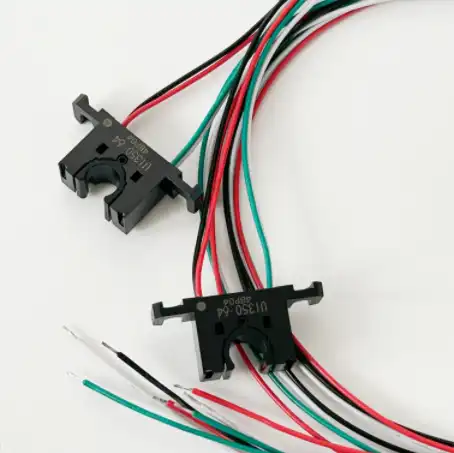

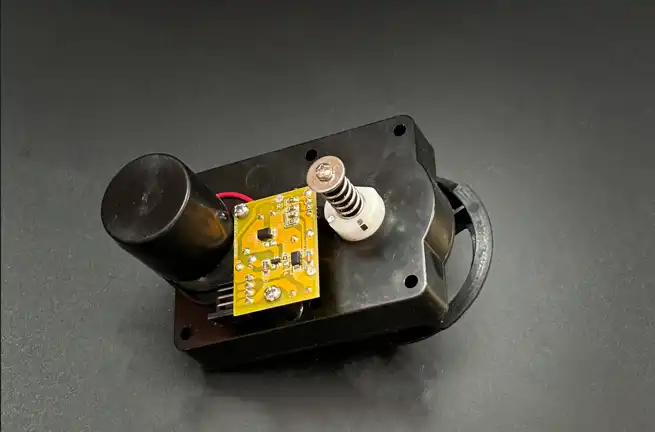

A gearbox and a small DC (Direct Current) motor are typically included in the construction of a screw vending machine motor. The motor can achieve high torque at relatively low speeds thanks to this combination, which is necessary for the controlled rotation of product spirals. The engine shaft is associated with the twisting loop, either straightforwardly or through a coupling instrument, empowering the engine to drive the winding's turn.

The functioning guideline of a screw engine in a vending machine spiral motor is direct yet compelling. The control system signals the appropriate motor when a customer makes a choice. The motor then spins the spiral coil a predetermined number of times, typically just enough to cause the selected item to fall into the dispensing area from the coil's end. The accuracy of the inventory is maintained and product waste is prevented by this precise control, which ensures that only one item is dispensed per transaction.

The control framework for Vending Machine Spiral Motor in the product is regularly founded on microcontrollers or programmable rationale regulators (PLCs). These frameworks can unequivocally control the pivot of each engine, considering changes in view of the size and weight of various items. High level control frameworks may likewise consolidate criticism systems, like optical sensors or engine encoders, to confirm fruitful item apportioning and identify any jams or breakdowns.

The adaptability of screw motors in vending machines is one of their primary advantages. By changing the pitch and width of the twisting curls, these engines can oblige an extensive variety of item sizes and shapes. This adaptability permits vending machine spiral motor administrators to change their item contributions without significant alterations to the machine's mechanical frameworks without any problem.

Motor Selection Factors

It is essential to select the appropriate motors for vending machines in order to guarantee their dependable operation and customer satisfaction. A few variables become an integral factor while picking engines, especially for screw vending machine spiral motor applications. Torque, speed, dependability, and energy efficiency are some of these factors.

When choosing a screw motor, torque may be the most important consideration. The engine should give adequate force to turn the winding curl, in any event, when it's completely stacked with items.

The measurement and pitch of the winding loop, as well as the weight and size of the things being apportioned, can all affect the necessary force.

Based on these factors, engineers typically determine the required torque and choose a motor that can consistently deliver it over its lifetime.

Speed is another important factor, although slower speeds are frequently preferred for screw motors. A more slow turn considers more exact command over item administering and lessens the gamble of things being catapulted too powerfully. Most screw engines in spiral motors work at speeds somewhere in the range of 10 and 20 RPM (cycles each moment), with the specific speed frequently being flexible through the control framework.

Dependability is central in Vending Machine Spiral Motor, as these machines are supposed to work consistently with negligible support. Vending machine motors need to be able to withstand numerous start-stop cycles and provide consistent performance for extended periods of time. This prerequisite frequently prompts the choice of brushless DC engines, which offer longer life expectancies and require less support contrasted with brushed engines.

Energy proficiency is turning into an undeniably significant figure engine determination for vending machine spiral motors. Even small improvements in motor efficiency can result in significant energy savings over time with many machines operating around the clock. Present day screw engines for candy machines frequently consolidate energy-proficient plans and materials to limit power utilization without compromising execution.

Notwithstanding these general variables, spiral motor engines have a few explicit prerequisites. In order to fit within the constrained space of a vending machine's product columns, they must be compact. They ought to likewise work unobtrusively to abstain from upsetting clients or the general climate. In addition, these motors need to be able to withstand the occasional impacts and vibrations that are a part of normal vending machine operation.

The overall design of the vending machine must also be taken into account when selecting the appropriate motors. Factors, for example, the machine's power supply (AC or DC), control framework similarity, and actual mounting choices all assume a part in deciding the most reasonable engine for a specific application.

Spiral Vending Machine Motor Manufacturers

Topping Motor has more than 10 years of experience and With a large inventory and complete certificates. If you are choosing your Vending Machine Spiral Motor supplier, welcome to contact us at sales@huan-tai.org.

When selecting a manufacturer for vending machine spiral motors, it's crucial to consider factors such as the company's experience, product quality, and ability to meet specific requirements. Topping Motor's decade-long presence in the industry suggests a wealth of expertise in designing and producing motors for vending machine applications.

The company's large inventory indicates their ability to meet diverse needs and potentially offer quick turnaround times for orders. This can be particularly beneficial for vending machine operators and manufacturers who need to quickly replace motors or scale up their production.

Certifications are another important aspect to consider when choosing a motor supplier. Topping Motor's complete certificates suggest that their products meet industry standards for quality and safety. This can provide peace of mind to vending machine manufacturers and operators, ensuring that the motors they use comply with relevant regulations and perform reliably.

In conclusion, the motors used in vending machines, particularly screw or spiral motors, play a crucial role in the reliable and efficient operation of these ubiquitous machines. The selection of these motors involves careful consideration of various factors to ensure optimal performance and longevity.

As distributing innovation keeps on developing, we can hope to see further progressions in engine plan and proficiency, adding to considerably more solid and energy-effective vending machine spiral motors from now on.

References

1. Smith, J. (2022). Vending Machine Technology: Principles and Applications. Journal of Automated Retail.

2. Johnson, A., & Lee, B. (2023). DC Motor Applications in Modern Vending Systems. IEEE Transactions on Industrial Electronics.

3. Garcia, M. (2021). Energy Efficiency in Vending Machine Motors: A Comparative Study. Energy and Buildings.

4. Brown, D., & Wilson, E. (2022). Control Systems for Precision Dispensing in Vending Machines. International Journal of Control, Automation and Systems.

5. Thompson, R. (2023). Advancements in Spiral Motor Design for Snack Vending Applications. Journal of Electromechanical Systems.

Send Inquiry

Related Industry Knowledge

- How often do you clean a Coffee Bean Hopper?

- Why do we use volumetric counter?

- How do you make coffee with a sieve?

- Can You Adjust the Boiler Temperature in Coffee Machines?

- How Does Motor Power Affect Coffee Grinding Speed?

- What Types of Motors Are Used in Coffee Grinders?

- Are Automatic Cup Dispensers More Efficient Than Manual Ones?

- Do I need a grinder for an espresso machine?

- How does a Coffee Machine Pump work?

- What does a Coffee Vending Machine Ingredient Canisters do?

.webp)