What does a solenoid valve do in an espresso machine?

2024-09-19 11:38:36

Espresso machine valve is a crucial component in espresso machines, playing several important roles that contribute to the quality and consistency of espresso production. These small but essential parts regulate water flow, control pressure, manage steam production, facilitate cleaning, and ensure safety. Understanding how valves function in espresso machines can help coffee enthusiasts and professionals alike appreciate the complexity behind their favorite brew and maintain their equipment effectively.

Water flow regulation

One of the primary functions of espresso machine valve is to regulate water flow. The main valve responsible for this task is often called the brew valve or group valve. It controls the flow of hot water from the boiler or heat exchanger to the group head, where the coffee grounds are held.

When a barista starts the brewing process, the brew valve opens, allowing pressurized hot water to flow through the coffee puck. The precision of this valve is crucial, as it needs to open and close quickly and consistently to ensure that each shot receives the same amount of water under the same conditions.

In advanced machines with pressure profiling capabilities, the brew valve may be electronically controlled. This allows for dynamic adjustment of water flow during extraction, enabling baristas to create custom pressure profiles that can enhance different flavor attributes of the coffee.

Some high-end machines even use multiple valves in the brew path for even more precise control. For example, a machine might have separate valves for pre-infusion (the initial wetting of the coffee grounds at low pressure) and the main extraction phase.

Pressure control

Pressure control is another critical function of espresso machine valve. The ideal pressure for espresso extraction is generally considered to be around 9 bars, although this can vary depending on the specific coffee and desired outcome.

The primary espresso machine valve responsible for pressure control is the expansion valve, also known as the over-pressure valve (OPV). Located after the pump and before the group head, its main function is to limit the maximum pressure in the system by allowing excess water to bypass back to the reservoir or drain when the set pressure is exceeded.

The expansion valve is usually adjustable, allowing technicians or advanced users to fine-tune the maximum pressure of the machine. This adjustment can be crucial for optimizing extraction based on different coffees or personal preferences.

Many modern espresso machines also incorporate a pre-infusion valve. This valve allows for a gentler start to the extraction process by introducing water to the coffee puck at a lower pressure before ramping up to full brewing pressure. This can help achieve more even extraction and reduce channeling, especially with lighter roasts or more delicate coffees.

Steam production

Steam production is vital in espresso machines, particularly for preparing milk-based drinks like cappuccinos and lattes. The main component in the steam system is the steam valve, which controls the flow of steam from the boiler to the steam wand.

The steam valve needs to be robust and precise, able to withstand high temperatures and pressures while offering smooth operation for the barista. Many professional-grade machines use quarter-turn valves for steam control, allowing for quick and precise adjustments to steam flow.

In dual-boiler or heat exchanger machines, there may be additional valves that help manage the interaction between the steam and brew water systems. For example, anti-vacuum valves prevent a vacuum from forming in the steam boiler as it cools down, which could potentially suck milk or other contaminants back into the system.

Backflush valve

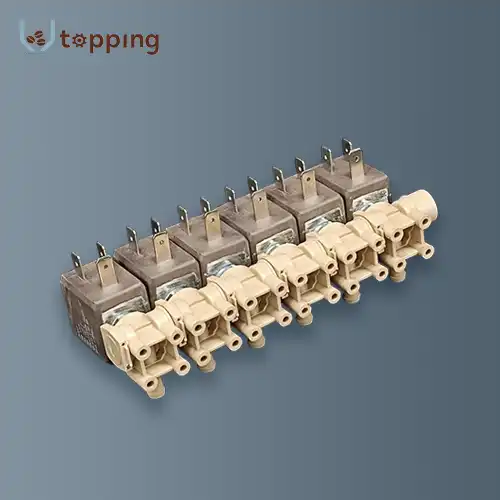

The backflush valve, also known as the 3-way solenoid valve or exhaust valve, is a critical component in many espresso machines. Its primary function is to relieve pressure in the group head immediately after the brewing process ends.

When an espresso shot is finished and the pump is turned off, there is still pressure in the group head. The backflush valve opens a pathway for this residual pressure and water to be released, typically into the drip tray. This quick depressurization creates a drier, more easily removable coffee puck, helps prevent over-extraction, and reduces dripping from the portafilter after the shot is complete.

The backflush valve also plays a crucial role in the machine cleaning process. During backflushing, a cleaning detergent is placed in a blind filter, and the brewing process is activated. The backflush valve allows this cleaning solution to be forced back through the system, cleaning the internal pathways and valves.

Safety valve

The safety valve, also known as a pressure relief valve, is a critical component that helps prevent dangerous over-pressurization of the boiler. While it may not be involved in the day-to-day brewing process, its role in ensuring the safe operation of the machine is crucial.

The primary function of the safety valve is to release excess pressure from the boiler if it exceeds a safe level. This could happen due to various reasons, such as a malfunctioning thermostat causing overheating, a faulty pressure stat, or a blockage in the steam system.

Typically, the safety valve is calibrated to open at a pressure significantly higher than the normal operating pressure of the machine. When the pressure in the boiler reaches this threshold, the safety valve opens, allowing steam to escape and reducing the pressure to a safe level.

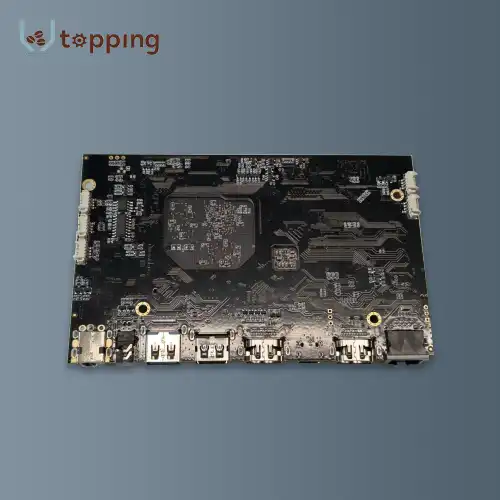

Valve Coffee Machine manufacturers

Topping Motor is an ISO 9001 certified company, specializing in producing various spare parts for coffee vending machines, including critical components like bean grinders, pumps, valves, and rings. With a global presence, they have been supplying these crucial parts to customers across several continents, including North America, Europe, Australia, and Asia.

For businesses or individuals looking for reliable valve manufacturers for espresso machine valve, Topping Motor can be contacted at sales@huan-tai.org. Their decade of experience in the field makes them a noteworthy option for those seeking quality components for coffee equipment.

In conclusion, valves play a multifaceted and crucial role in the operation of espresso machines. From regulating water flow and controlling pressure to managing steam production and ensuring safety, these small components are essential to producing high-quality espresso consistently and safely. Understanding the functions of these various valves can help baristas and technicians better maintain and troubleshoot their machines, ultimately contributing to better coffee experiences for all.

References:

1. Illy, A., & Viani, R. (2005). Espresso Coffee: The Science of Quality. Academic Press.

2. Schomer, D. (2004). Espresso Coffee: Professional Techniques. Espresso Vivace.

3. La Marzocco. (n.d.). Machine Manual: Linea Classic.

4. Rancilio Group. (n.d.). Technical Manual: Classe 9 USB.

5. Hendon, C. H., Colonna-Dashwood, L., & Colonna-Dashwood, M. (2014). The Role of Dissolved Cations in Coffee Extraction. Journal of Agricultural and Food Chemistry, 62(21),

4947-4950.

Send Inquiry

Related Industry Knowledge

- Why do we use volumetric counter?

- What are the specifications needed for the vending machine?

- What Is a Multi Boiler Coffee Machine?

- Universal control board for vending machine

- What are the sizes of vending machine touch screen?

- What Are the Key Components of a Coffee Vending Machine Dispensing System?

- Is a built-in coffee grinder worth it?

- How Long Does Coffee Last in Hopper?

- Do coffee machines have grinders?

- Why is Vending Coffee Machine Water Tank made of Food-grade plastic?

.webp)