What is the specific working process of the Control Board For Vending Machine?

2024-10-15 09:48:37

Introduction

The Control Board in a Vending Machine represents an amalgamation of technology designed to ensure seamless operation, effective transactions and product dispensing. It's essentially the 'brain' behind this autonomous machine, overseeing all aspects from acceptance of payment through cash or credit card readers to delivering products and recording each transaction.

Upon receiving power supply, the Control Board Vending Machine activates its system, engaging with every connected component including sensors for detecting the type and value of inserted currency, a display screen for customer interaction, coin/bill acceptors for payment reception, and dispensers for product delivery. It's powered by an MCU (Microcontroller Unit) that runs on specialized firmware designed specifically for vending operations.

The product initiates its operation with power-on sequence where it starts to initialize all connected peripherals. As a transaction begins — typically through a customer selection via touch screen or buttons — the product processes this data rapidly and precisely, utilizing advanced algorithms in sensors to ensure accurate value recognition of inserted money.

Further into the process, once payment verification is completed successfully by recognizing valid currency types and values, the system checks stock availability. It ensures that only authorized products are dispensed after confirming their availability against inventory records, preventing overstocking or understocking issues.

Security features in this control board are robust too — it logs every transaction meticulously for auditing purposes. Information such as product sold, quantity, time of sale and customer details is recorded in a database which also facilitates sales performance analysis, inventory management, and tracking customer preferences.

Moreover, alert systems are integrated into the product to notify users about any machine malfunctions or low stock situations ensuring maintenance can be carried out quickly without causing any inconvenience.

In essence, the product ensures that a Vending Machine operates smoothly, securely and efficiently, providing customers with an optimal purchasing experience while simultaneously maintaining operational effectiveness for the business.

System Architecture

The system architecture of a vending machine control board includes several critical components, each playing a unique role. The core of the control board is the microcontroller, which acts as the central processing unit. The microcontroller executes the software code that governs the machine's operations.

Memory components, such as RAM and ROM, are used to store operational data and the machine’s firmware. Input/output (I/O) interfaces connect various parts of the vending machine to the control board, including payment processors, selection buttons, and product dispensers. Other essential components include power supply units, communication modules, and sensors that monitor machine status and user interactions.

The microcontroller processes input signals from the I/O interfaces, executes predefined operations, and sends commands to the vending machine’s mechanical and electronic systems to perform tasks such as accepting payments and dispensing products.

Initialization and Self-Test

Upon booting up, the vending machine's Control Board embarks on an initial setup and diagnostic sequence aimed at confirming the operational status of all hardware components. This comprehensive process is executed by a microcontroller that acts as the main processor.

The initialization phase begins with verifying the adequacy of power supply to ensure there are no disruptions in energy flow. The self-diagnosis proceeds by establishing communication protocols with each connected device, which includes input and output devices alike.

A detailed integrity check on memory chips confirms their reliability for storing critical operational data. This is followed by testing the functionality of all input devices like buttons and payment systems to ensure seamless interaction. Simultaneously, it conducts checks on output components such as motors responsible for product dispensing mechanisms and LED displays that communicate transaction details to customers.

In this process, any anomaly in hardware operation can be detected early on. The control board employs corrective measures capable of addressing minor issues automatically where feasible. For significant malfunctions or maintenance needs, the system triggers error codes displayed prominently on the machine's screen for quick identification by technicians.

This systematic approach guarantees a smooth transition from power-on to operational state, thereby ensuring customer service continuity and enhancing overall efficiency in the vending machine’s performance cycle. It also prevents potential breakdowns due to overlooked hardware defects at an early stage, contributing significantly towards longer equipment lifespan and reduced maintenance costs.

Product Selection and Distribution

The product selection and distribution process is a critical function managed by the vending machine control board. When a user interacts with the machine, they typically input their selection through a keypad or touchscreen interface.

The control board receives this input, verifies the selection against the machine’s inventory, and processes the payment. Modern vending machines support various payment methods, including coins, bills, and electronic payments. The control board ensures the correct amount is received and verified using built-in sensors and validators.

Once the payment is validated, the control board activates the appropriate distribution mechanism. This can involve motors that rotate spiraled coils or conveyors that transport the selected item to the dispensing area. Advanced machines may use elevator-based systems for larger or fragile products to ensure they are delivered without damage.

Safety mechanisms, such as sensors to detect successful product delivery, are also managed by the control board to prevent issues like dispensing errors or theft.

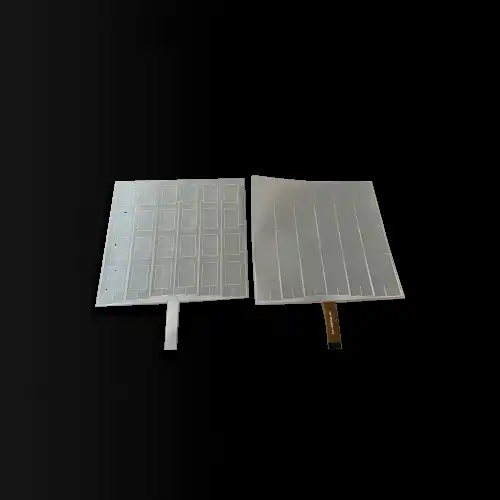

Control Board For Vending Machine Factory

Topping Motor is proud of its extensive 10-year history in the manufacturing industry specializing in control boards for vending machines. We have consistently provided superior quality products that cater to a wide variety of environmental conditions.

Our control boards are designed to withstand temperatures from as low as -20℃ up to an upper limit of 70℃. However, they perform most optimally within a more moderate range of 5℃ to 35℃. This ensures optimal performance throughout the year, regardless of seasonal changes.

We also guarantee durability and reliability under varying humidity levels, from 10% up to an acceptable peak of 90%. We ensure there's no condensation risk that might compromise performance or functionality.

If you're seeking a dependable partner for your vending machine control board needs, Topping Motor stands ready. We understand the importance of seamless operation and reliability in your business and are here to support your requirements.

Should you wish to know more about our products or initiate a partnership with us, kindly drop an email at sales@huan-tai.org. Our customer service team is always available to provide you with any information needed or answer all your inquiries promptly.

At Topping Motor, we're committed to making sure that your vending machine operations are as smooth and reliable as possible by offering top-tier control boards that match the challenging demands of real-world usage. We look forward to serving you and contributing towards the success of your business!

References

How Vending Machines Work: A Comprehensive Guide - Fraxotic Vending Machines

A complete guide of vending machine parts - Vending World

How Does A Vending Machine Work? - Vending Machine Guide

How Does a Vending Machine Work? - Bizfluent

Send Inquiry

Related Industry Knowledge

- What is a volumetric counter?

- How Quickly Do Coffee Machine Boilers Heat Up?

- What Does a Boiler Do in a Coffee Machine?

- Why is Hygiene Important in Vending Machine Cup Dispensers?

- How does a Vending Machine Spiral Motor work?

- What size sieve for removing fines from coffee?

- What safety standards and regulations need to be followed when designing vending machine circuit boards?

- What technologies are involved in upgrading the Vending Machine Board?

- Why it is important to store coffee making ingredients appropriately?

- How does the valve coffee machine work

.webp)

.webp)